Automatic Single Or Multi-piece Products Packaging Line

Automatic Packaging Line Typical Applications

- Bakery & Confectionery: Biscuits, cookies, cakes, bread slices, chocolate bars

- Frozen Foods: Dumplings, tangyuan, fish balls, meatballs

- Snacks & Convenience Foods: Instant noodle blocks, candy packs, puffed snacks

- Household & Industrial Products: Wet wipes (multi-piece), disposable masks, small hardware items

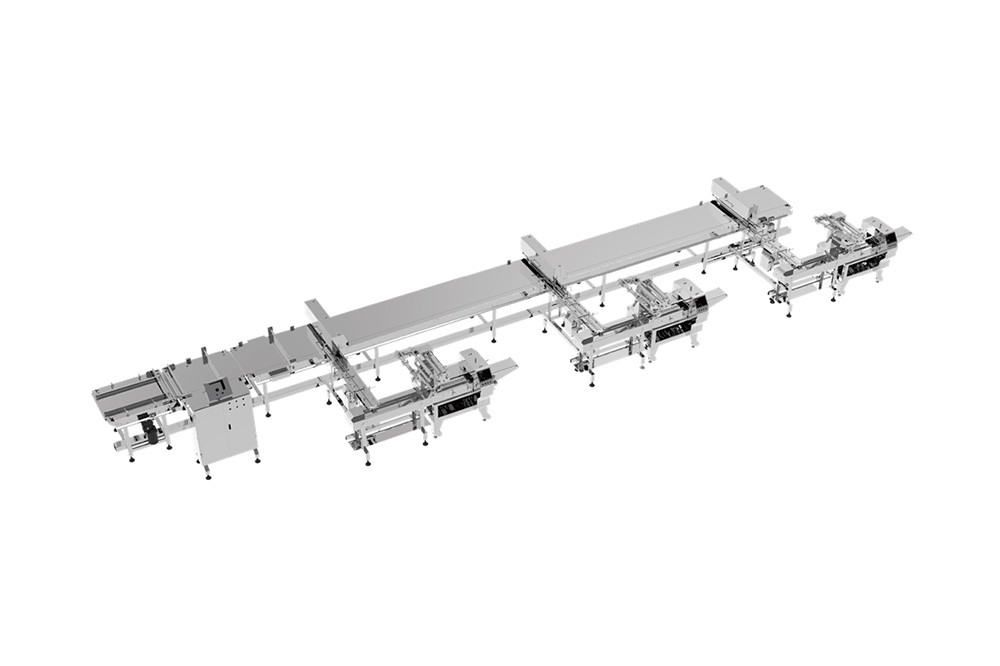

The Automatic Single or Multi-piece Products Packaging Line from Soontrue is designed to meet the versatile needs of modern food manufacturers. It offers flexibility, precision, and high-speed automation, making it suitable for both individual item packaging (such as a single biscuit or wafer) and multi-piece or multi-layer packaging (such as 2×5 rows or stacked formats like 2×5×2). From single snacks to family-sized packs, the system adapts seamlessly to different product types, ensuring efficiency and consistent quality.

How It Works

- Feeding & Sorting – Products enter the conveyor and are automatically aligned into single pieces or groups.

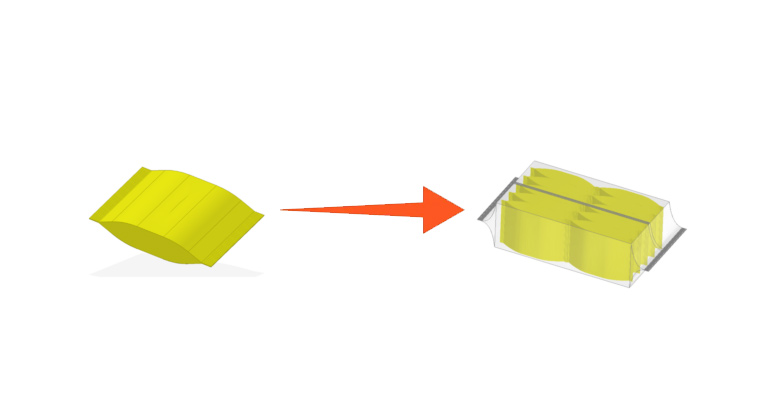

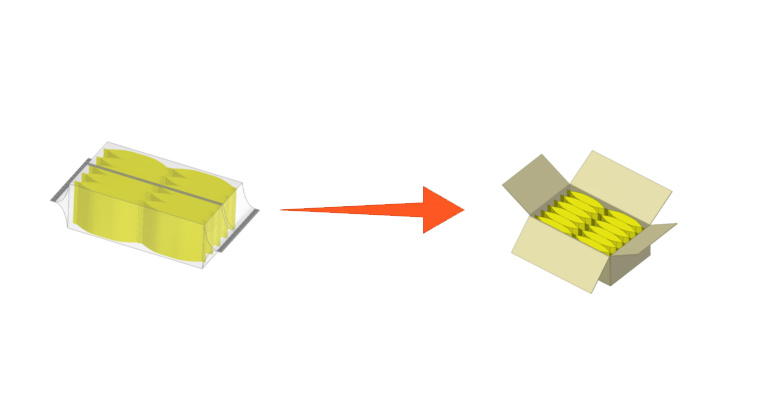

- Counting & Stacking – Servo-driven counters and stackers group items into precise quantities and arrange them neatly into rows or multi-layer formations (e.g., 2×5×2).

- Primary Packaging – Products are transferred into pillow packs, pouches, or trays, where sealing ensures product safety and freshness.

- Secondary Packaging (Optional) – Grouped packs can be automatically placed into cartons or cases, ready for storage or distribution.

👉 This process enables manufacturers to package both individually wrapped items and multi-piece family packs on the same line, reducing manual labor, improving consistency, and increasing throughput.

Machine Parameters

Key Features

Versatile Handling – Supports single units or multi-piece packs in one system

Precise Counting – Servo-driven counters ensure accurate product quantity

Neat Arrangement – Products can be aligned in rows or stacked into layers (e.g., 2×5×2) for stability

High-Speed & Consistent – Maintains production efficiency even with complex grouping

Flexible Integration – Can connect with cartoners, case packers, and palletizers

Food-Safe & Easy-Clean – Hygienic stainless steel design suitable for food industries

Application

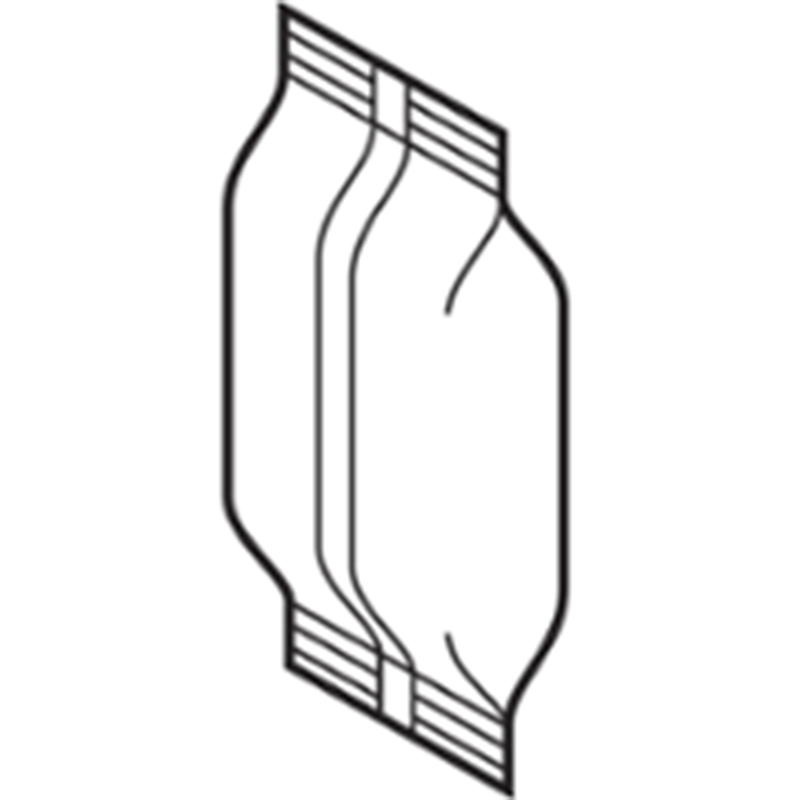

Bag Type

Competitive Advantage

Unlike traditional systems that require separate setups for single-piece and multi-piece packaging, Soontrue's solution combines both in one line. Our advanced counting and stacking technology ensures perfect alignment and zero counting errors, even for complex arrangements like 2×5×2. The flexibility of our design allows customers to quickly switch between different formats without major adjustments, significantly reducing downtime. With integrated servo control, smart fault detection, and scalable modules, Soontrue delivers a packaging line that is faster, more precise, and more adaptable than competing solutions on the market.

Why Choose Soontrue?

As a leading innovator in packaging automation, Soontrue offers tailor-made solutions that help manufacturers improve efficiency, consistency, and product presentation. With over 30 years of industry experience, we understand the unique needs of food and consumer goods production. Our global service network ensures rapid technical support and spare parts supply, while our engineering expertise guarantees smooth installation and long-term reliability. Choosing Soontrue means investing in a partner who combines cutting-edge technology, practical customization, and world-class service to keep your production ahead of the competition.

FAQ About Automatic Single or Multi-piece Products Packaging Line

Q1: Can the line handle both single and multi-piece products on the same system?

Yes. Our system allows fast changeovers between single and multi-piece packaging formats.

Q2: What stacking formations are supported?

The line can arrange products in rows, groups, or layered stacks such as 2×5×2, depending on product type and packaging requirements.

Q3: Will the line reduce manual labor?

Yes. It automates sorting, counting, and stacking, significantly reducing manual handling.

Q4: Is the line customizable?

Absolutely. Each solution is designed based on the customer's product, speed requirements, and factory layout.

Q5: What industries benefit most from this line?

Food (bakery, frozen, snacks), personal care, and light industrial sectors requiring precise and consistent packaging.