DKXM-500 Box Erecting Machine

DKXM-500 Box Erecting Machine Typical Applications

- Food & Beverage: snacks, baked goods, bottled drinks, dairy products

- Pharmaceuticals & Healthcare: medicines, medical devices, daily care products

- Household Products: tissues, cleaning supplies, disposables

- Industrial Goods & Hardware: spare parts, tools, accessories

- Logistics & Warehousing: shipping cartons and e-commerce packaging

The DKXM-500 is a servo-driven automatic case erector designed for efficient box forming and bottom sealing in packaging lines. Unlike robotic arm-based models, which offer maximum flexibility but higher costs, the DKXM-500 uses servo control to directly open cartons, achieving stable, precise forming at a speed of up to 900 cartons/hour.

It provides two bottom sealing methods — hot-melt glue spraying or adhesive tape sealing — enabling manufacturers to choose based on product, cost, and strength requirements. With its compact structure and servo-driven stability, the DKXM-500 delivers reliable performance for both small and large cartons.

Positioned as a cost-effective alternative to robotic case erectors, the DKXM-500 balances speed, affordability, and accuracy, making it an ideal choice for manufacturers seeking high throughput without the higher investment of robotic systems.

Machine Parameters

| Specifications | DKXM-500 | DKXL-650 |

| Box size range | L 280-500 mm | L 280-660 mm |

| W 150-400 mm | W 180-500 mm | |

| H 150-400 mm | H 150-500 mm | |

| Erecting speed | 5-15 cases/min | 5-15 cases/min |

| General power | 1 Kw | 8.0 Kw |

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz |

| Machine weight | 320 kg | 450kg |

| Machine dimensions | 1950x1800x1400 mm | 2300x2030x1573 mm |

| Adhesive tape | W48, W60, W75 | W48, W60, W75 |

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

- Servo-Controlled Box Erecting: The DKXM-500 is driven by a servo motor system, which controls the box erecting process with high precision. This setup provides consistent and reliable performance, reducing the chances of box damage and misalignment during the opening process.

- Dual Bottom Sealing Options: The machine offers both glue spraying and adhesive tape sealing for the bottom of the boxes. This flexibility allows manufacturers to choose the most suitable sealing method based on the type of product, ensuring that the boxes remain securely sealed during handling and transport.

- Wide Range of Box Sizes: The DKXM-500 can accommodate a broad range of box dimensions, from 280 mm to 500 mm in length and 150 mm to 400 mm in height, making it adaptable to various packaging requirements across different industries.

- Compact and Durable Design: Built with a carbon steel frame, the DKXM-500 is designed for durability and long-term operation. The machine's compact dimensions (1950 x 1800 x 1400 mm) allow for easy integration into existing production lines, without requiring excessive floor space.

- External Compressed Air Requirement: The machine operates with an external compressed air source, ensuring smooth and uninterrupted performance in high-speed production environments.

- Efficient Sealing Speed: With a speed of 5 to 15 cases per minute, the DKXM-500 supports efficient and reliable case erection in medium to high-output production lines, enhancing the overall productivity of the packaging process.

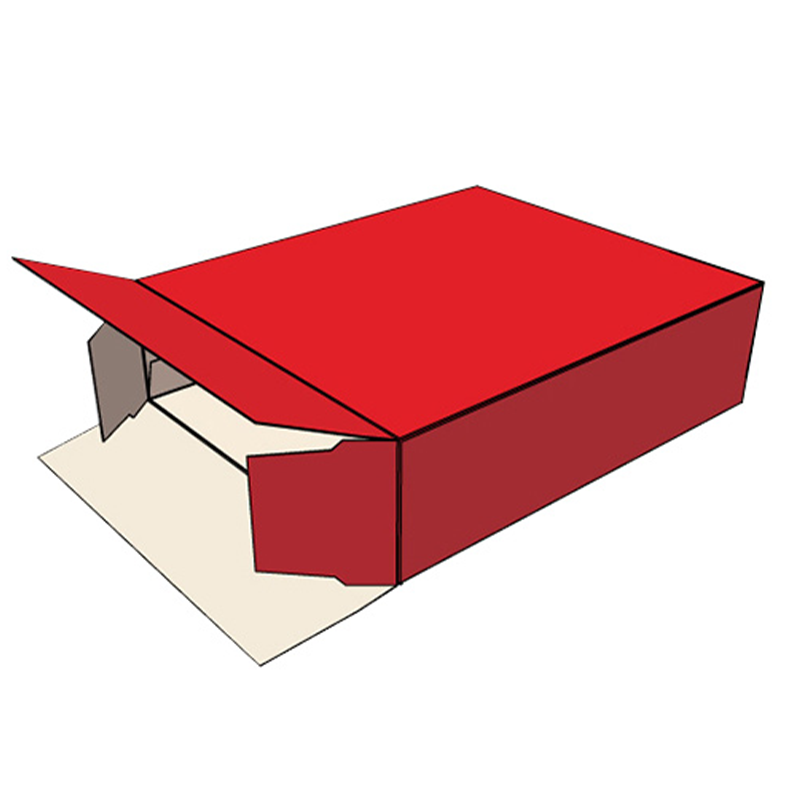

Bag Type

Competitive Advantage

Compared with robotic box erectors, the DKXM-500 offers a faster yet more economical solution for standard carton forming. While robotic systems provide maximum flexibility, they are often more expensive. The DKXM-500 achieves up to 900 cartons/hour, outperforming many entry-level robotic models in speed.

Compared to traditional mechanical case erectors, which may suffer from inconsistent forming or limited sealing options, the DKXM-500's servo-driven precision and dual sealing methods ensure consistent quality and adaptability. For buyers prioritizing throughput, reliability, and affordability, the DKXM-500 provides an attractive balance of performance and cost.

Why Choose Soontrue?

With decades of experience in packaging automation, Soontrue offers solutions tailored to every production scale. The DKXM-500 Box Erecting Machine is part of our portfolio of servo-driven and robotic case erectors, giving buyers the freedom to choose based on speed, budget, and application. Backed by a global support network, fast installation, and spare parts supply, Soontrue ensures long-term reliability and faster ROI for every investment.

FAQ - DKXM-500 Box Erecting Machine

Q1: What is the maximum speed of the DKXM-500?

It can erect up to 900 cartons per hour, making it one of the fastest servo-driven case erectors in its class.

Q2: What sealing methods does it support?

The machine supports both hot-melt glue spraying and adhesive tape sealing, giving buyers flexibility for cost and strength.

Q3: Is it suitable for different carton sizes?

Yes. The servo-driven system enables quick adjustments for various carton sizes with minimal downtime.

Q4: What industries use the DKXM-500?

It is widely applied in food, beverages, pharmaceuticals, household goods, and logistics.

Q5: What makes the DKXM-500 cost-effective?

It provides high speed and precision at a lower investment than robotic models, making it ideal for businesses focused on efficiency and ROI.