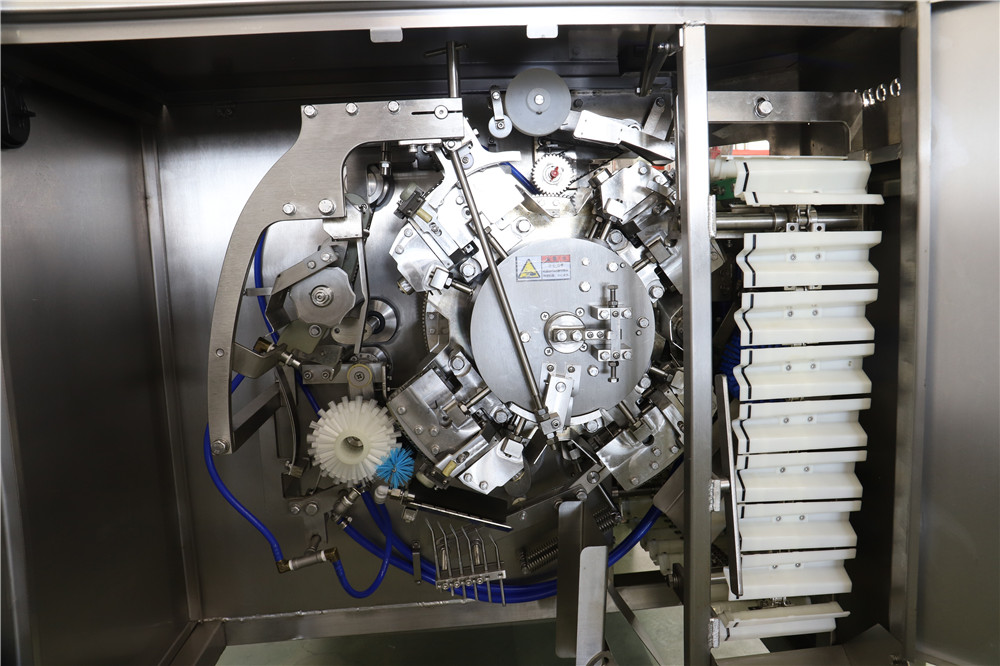

Hb320 Shrimp Peeling Machine

HB320

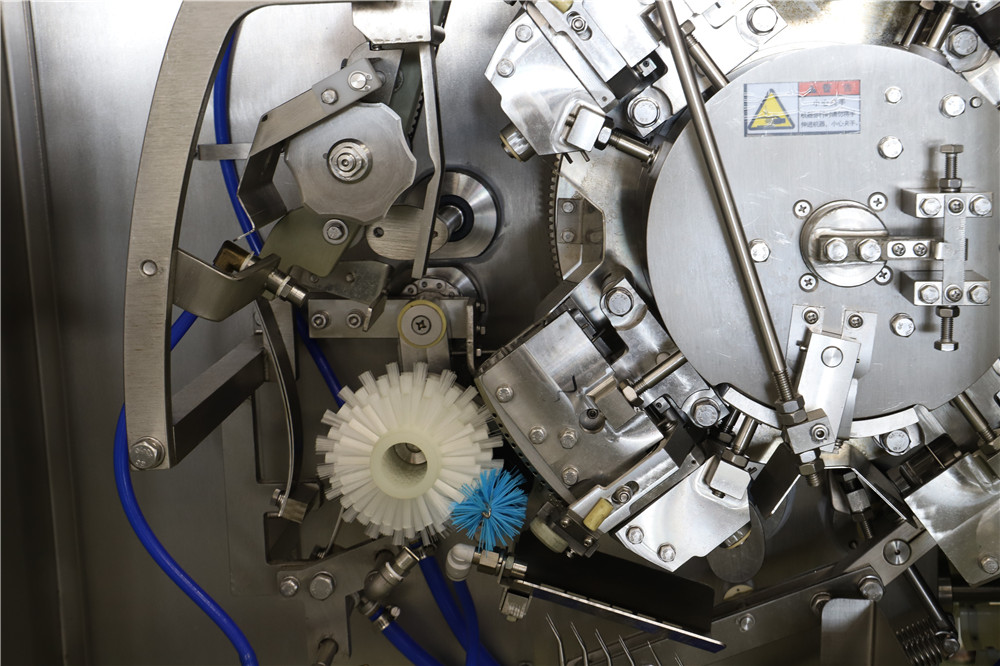

- Servo control

- Stainless steel machine body

- Different peeling styles compatible

- IP65

Our shrimp peeling machine is engineered for high-efficiency, reliable, and precise shrimp processing, offering a fully automated solution for peeling and deveining shrimp across various sizes and styles. It’s ideal for seafood processing companies aiming to enhance production speed, consistency, and hygiene standards.

Machine-Processed vs. Hand-Processed Shrimp

Machine-processed shrimp provide a level of consistency and hygiene that’s challenging to achieve with manual labor. Automated processing ensures uniform appearance, precise skin thickness, and minimizes handling, which reduces contamination risks. Additionally, automation significantly speeds up production, reducing labor costs and increasing output while maintaining strict hygiene standards.

Competitive Advantage

Compared to traditional shrimp peeling machines that require manual adjustments and lengthy downtime to switch processing styles, our machine offers a streamlined solution with just one touch. The advanced HMI and servo control allow operators to change processing modes instantly, significantly reducing downtime and ensuring continuous, high-quality production.

With its advanced design, ease of operation, and ability to integrate into a complete production line, our shrimp peeling machine is the ideal choice for seafood processors seeking high-efficiency, consistent quality, and flexibility in meeting diverse market demands.

Machine Parameters

| Specifications | HB320 | ||||

| Shrimp spec | From 21/25 to 71/90 | ||||

| Peeling speed | Max. 70 pcs/min | ||||

| Water consumption | 120 L/h | ||||

| Water pressure | 0.4 mpa | ||||

| Greneral power | 1.5 Kw | ||||

| Power suppky | 220v/1Ph/50hz | ||||

| Machine weight | 230 kg | ||||

| Machine size | 1186×832x1274 mm | ||||

Key Features

- IP65 Waterproof Design with Display Shield

Designed for high-moisture environments, our shrimp peeling machine features an IP65 waterproof design, ensuring durability and resilience. The display screen has a waterproof shield, allowing for easy operation even under wet conditions.

- Quick Processing Style Change via Advanced HMI

Unlike conventional machines that require extensive adjustments, taking 30 minutes or more to switch processing styles, our shrimp peeling machine allows for a quick and seamless transition. Simply select the desired processing style on the touch screen, and the machine automatically adjusts its settings. This reduces downtime and increases production flexibility, making it easy to adapt to diverse consumer preferences and market demands.

- Multiple Processing Styles

This machine offers a wide range of processing options, including E-Z peeling, tail-on or tail-off, butterfly split, and more. The versatility enables businesses to meet specific customer and export requirements, providing tailored products for different markets.

- Seamless Integration into Production Lines

Our shrimp peeling machine is designed to be modular and can be easily integrated into a complete shrimp processing line. By combining it with additional equipment, you can create a fully automated production line that streamlines every stage of shrimp processing—from peeling to packing. This reduces manual labor, maximizes efficiency, and enhances productivity for large-scale operations.

- Versatile Peeling Capability: Handles shrimp sizes ranging from 21/25 to 71/90, making it adaptable for various market needs. Capable of producing up to 70 peeled shrimps per minute, ensuring high output.

- Multiple Processing Styles: Supports various peeling styles, including E-Z Peeling, Tail-On (2 to 4), Tail-On Deep Cut, Butterfly Split, Gradual Cut, Tail-Off Completely Peel, Shell Split, and Tail-On Completely Split. This flexibility enables processors to meet diverse consumer and market preferences.

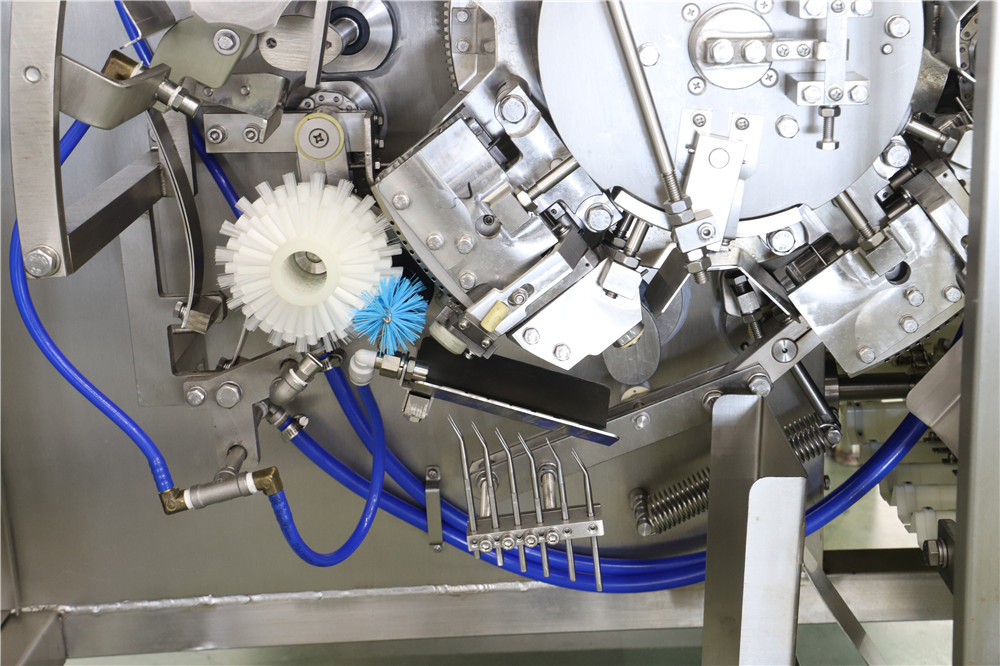

- Servo Control System: The servo control reduces mechanical transmission needs, simplifying the machine's maintenance and commissioning process while ensuring accuracy and reliability in the peeling process.