KXM-500 Robotic Box Erecting Machine

KXM-500 Robotic Box Erecting Machine Typical Applications

- Food & Beverage: packaged snacks, bakery, dairy, and beverages

- Pharmaceuticals & Healthcare: medicines, medical devices, and personal care items

- Household Products: tissues, cleaning products, daily consumables

- Industrial Goods & Electronics: hardware, spare parts, and appliance packaging

- Logistics & E-commerce: carton forming for large-scale distribution centers

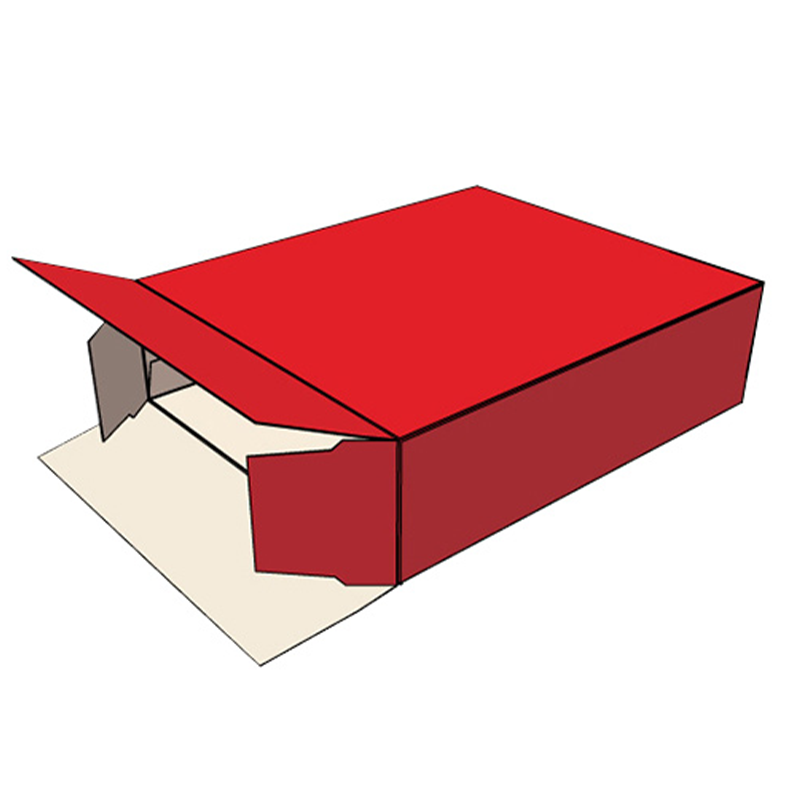

The KXM-500 Robotic Box Erecting Machine is a high-performance solution designed to automate the carton erection process for high-demand packaging lines. Equipped with advanced robotic arms, it grabs and opens flat-packed boxes, ensuring precise forming before securely sealing the bottom.

The machine offers two flexible bottom-sealing options — hot-melt glue spraying or adhesive tape sealing — giving manufacturers the versatility to adapt to different packaging requirements. Powered by five servo motors, the KXM-500 ensures smooth, stable, and accurate operation across various carton sizes.

With its combination of high speed, sealing flexibility, and servo-driven accuracy, the KXM-500 is an ideal choice for manufacturers that need a reliable, efficient, and customizable case erecting solution. Whether applied in food, beverage, household, or industrial packaging, it provides a robust foundation for fully automated production lines.

Machine Parameters

| Specifications | KXS-400 | KXM-500 | KXL-650 | TKXS-400 | TKXM-500 |

| Servo control | 5 | 5 | 5 | 3 | 3 |

| Box size range | L 145-430 mm | L 280-500 mm | L 280-650 mm | L 145-420 mm | L 280-500 mm |

| W 85-350 mm | W 150-400 mm | W 180-500 mm | W 80-350 mm | W 150-400 mm | |

| H 105-350 mm | H 150-400 mm | H 150-500 mm | H 150-350 mm | H 150-400 mm | |

| Erecting speed | 5-30 caseses/min | 5-30 caseses/min | 5-25 caseses/min | 15-25 caseses/min | 15-25 caseses/min |

| General power | 2.1 Kw | 2.1 Kw | 2.35 Kw | 2.3 Kw | 3.0 Kw |

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz |

| Machine weight | 620kg | 620kg | 880kg | 550 kg | 620kg |

| Machine dimensions | 2400x1900x1350 mm | 2845x2000x1400 mm | 2920x2100x1500 mm | 2400x1900x1400 mm | 2600x2000x1450 mm |

| Adhesive tape | W30-W50 | W48, W60, W75 | W48, W60, W75 | W50mm or below | W50mm or below |

| View Machine | |||||

Key Features

- 5 Servo Motor Control System: Equipped with 5 advanced servo motors, the KXM-500 delivers precise control over the robotic arm movements, ensuring high accuracy when absorbing and opening boxes. This leads to perfectly shaped cartons and reduces the chances of errors in the box erection process.

- Robotic Case Erecting: The robotic arms automatically absorb, lift, and open the flat boxes with high precision, minimizing manual intervention. This ensures that the machine operates efficiently in high-speed production environments while maintaining consistent quality.

- Dual Bottom Sealing Methods: The KXM-500 offers both glue spraying and adhesive tape sealing for the bottom of the cartons. This flexibility allows manufacturers to select the most appropriate sealing method based on the product weight and packaging requirements, ensuring secure and stable sealing.

- Wide Box Size Range: The machine can handle a wide range of box dimensions, from 280 mm to 500 mm in length, and 150 mm to 400 mm in width, making it adaptable to various packaging needs across industries. It can easily accommodate boxes used for different product types, from small to large cartons.

- Carbon Steel Machine Body: Built with a durable carbon steel frame, the KXM-500 ensures long-lasting performance even in demanding production conditions. Its robust design guarantees that the machine will withstand wear and tear while maintaining consistent operation.

- External Compressed Air Requirement: The machine requires an external compressed air source, which powers the sealing mechanisms and ensures efficient and uninterrupted operation during continuous high-speed production.

- High-Speed Operation: Capable of erecting between 5 to 30 cases per minute, the KXM-500 supports high-output production lines, improving throughput and reducing the need for manual labor. Its fast and reliable operation ensures packaging lines run smoothly.

- Compact Design: Despite its powerful capabilities, the KXM-500 has a relatively compact footprint, with dimensions of 2845 x 2000 x 1400 mm, making it easy to integrate into existing packaging lines without taking up excessive space.

Bag Type

Competitive Advantage

The KXM-500 Robotic Box Erecting Machine stands out by delivering up to 1,500 cartons per hour, far surpassing the capacity of most traditional and competitor models. While many case erectors struggle with carton jamming, slow changeovers, or limited sealing options, the KXM-500 combines robotic precision with five servo-driven motors to ensure smooth, stable, and accurate carton forming.

Its dual bottom-sealing methods (hot-melt glue or adhesive tape) provide buyers with flexibility for different product lines and cost preferences, while the quick-adjust design minimizes downtime between carton sizes. This combination of speed, flexibility, and reliability makes the KXM-500 a superior choice for businesses aiming to scale up end-of-line efficiency and reduce operating costs.

Why Choose Soontrue?

By choosing Soontrue, you partner with a global leader in packaging automation backed by 30+ years of experience. The KXM-500 reflects Soontrue’s commitment to delivering high-speed, robotics-driven box erection solutions that align with the needs of modern manufacturing. Buyers benefit from:

- Proven engineering: Machines designed for continuous, 24/7 operation.

- Global support: Installation, training, and after-sales service worldwide.

- Flexibility & customization: Adaptable sealing options and carton formats.

- Faster ROI: High throughput reduces labor costs and maximizes output.

With Soontrue, you get not only advanced equipment but also a reliable partner to optimize long-term production performance.

FAQ - KXM-500 Robotic Box Erecting Machine

Q1: What is the maximum speed of the KXM-500?

The machine can erect up to 1,500 cartons per hour, making it one of the fastest robotic box erecting solutions in the market.

Q2: What bottom-sealing options does it provide?

It offers two methods: hot-melt glue spraying or adhesive tape sealing, allowing manufacturers to choose based on cost, carton type, or strength requirements.

Q3: Can it handle different carton sizes?

Yes. The servo-driven system allows quick changeovers between various carton sizes with minimal downtime.

Q4: How does the KXM-500 improve efficiency compared with manual or semi-automatic systems?

It reduces labor needs, eliminates inconsistent carton forming, and ensures stable, precise erection even at high speeds.

Q5: What industries can benefit from this machine?

The KXM-500 is suitable for food & beverage, pharmaceuticals, daily goods, electronics, and logistics, or any industry requiring reliable high-speed case erection.

Q6: How does Soontrue support after installation?

Soontrue provides on-site installation, operator training, spare parts supply, and remote technical support, ensuring smooth operation and long-term reliability.