YL400A Liquid Vertical Packaging Machine

YL400A Liquid Vertical Packaging Machine Typical Applications

- Dairy products: milk, yogurt, cream.

- Beverages: juices, flavored drinks, soy milk.

- Sauces & condiments: ketchup, mayonnaise, chili sauce, soy sauce.

- Cooking oil: edible oil, olive oil, sesame oil.

- Personal care & chemicals: shampoo, liquid soap, detergent, lubricants.

The Soontrue YL400A is the definitive solution for leak-proof and hygienic liquid packaging. Specifically engineered as a liquid and paste packaging machine, it addresses the common challenges of product waste, seal contamination, and inconsistent filling that plague standard VFFS machines.

From free-flowing milk and juices to viscous sauces and creams, the YL400A's customizable pump systems ensure precise, anti-drip dosing every time. Its robust, multi-layer heat sealing technology creates durable, reliable seals that withstand transport and handling. This machine is the trusted choice for any business in the dairy, food, beverage, or chemical industries seeking to automate and perfect their liquid packaging process.

Machine Parameters

| Specifications | YL400A |

| Bagging size range | L100-450 mm |

| W105-260 mm | |

| Packaging material | Liquid, high viscosity fluid |

| Filling capacity | 500 - 5000 g |

| Packing speed | 4-20 bags/min |

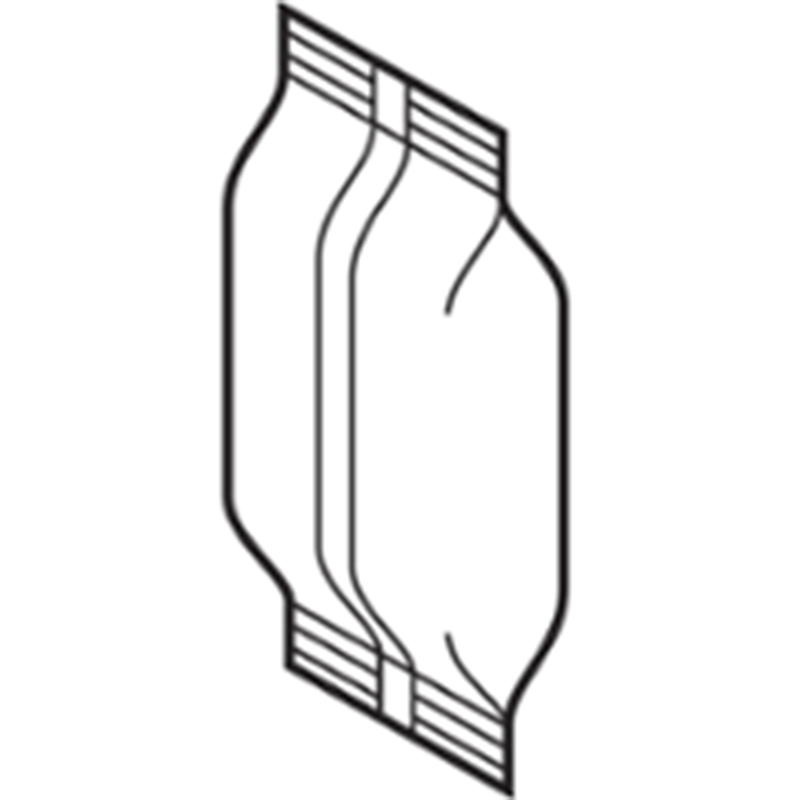

| Pouch type | Pillow pouch |

| General power | 4.0 Kw |

| Power supply | 380V/3Ph/50Hz |

| Machine weight | 700kg |

| Machine dimensions | 1800x1105x1960 mm |

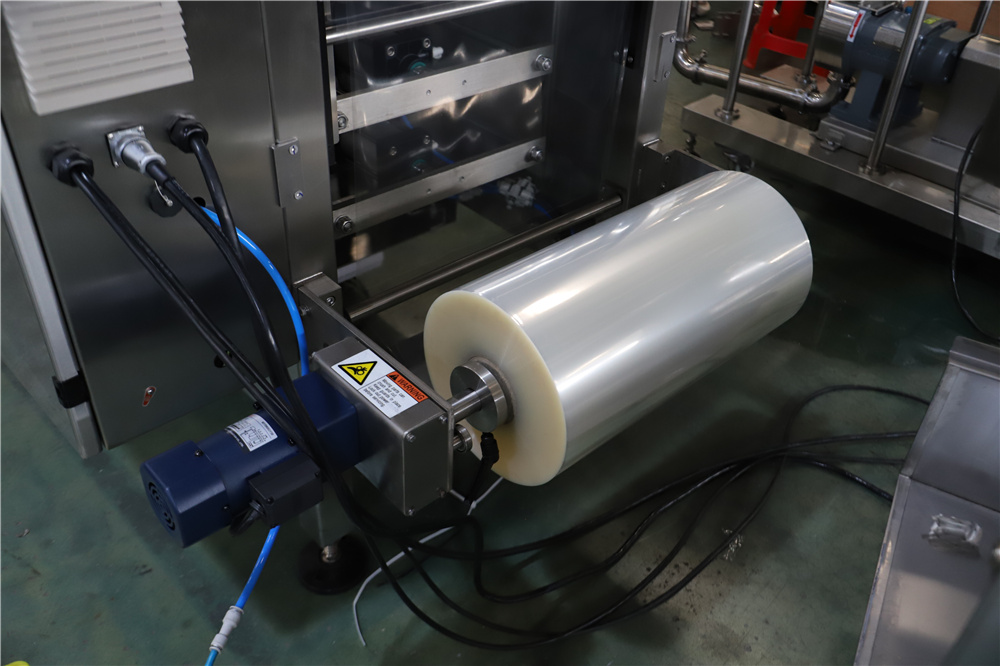

| Packing material |

Laminated film, NY/PE etc. |

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

- Wide Liquid Compatibility:Capable of handling low-viscosity liquids (water, juice, milk) and high-viscosity pastes (sauces, creams, condiments) with interchangeable filling systems.

- Precision Dosing Control:Equipped with servo-driven piston or peristaltic pumps, ensuring consistent filling volume within ±1% accuracy, reducing product giveaway and waste.

- Advanced Leak-Proof Sealing:Adopts multi-layer heat sealing with precise temperature control, ensuring durable seals that withstand transportation and storage without leakage.

- Flexible Bag Styles:Supports pillow bags, gusseted bags, and small sachets directly from film rolls, adapting to different retail and distribution needs.

- High Hygiene Standards:Built with 304/316 stainless steel contact parts and CIP (clean-in-place) options, meeting food safety, dairy, and GMP requirements.

- Quick Changeover & Easy Cleaning:Tool-free adjustments and detachable liquid-contact components allow for fast product changeovers, minimizing downtime.

- User-Friendly Operation:Integrated HMI touchscreen with multi-language interface, recipe memory, and error detection for easy use by operators of different skill levels.

- Compact, Space-Saving Design:Vertical layout reduces footprint, making it suitable for factories with limited floor space while maintaining high throughput.

Application

The YL400A's purpose-built design makes it a premier choice across multiple industries requiring precise and hygienic liquid packaging. Whether you require a fully hygienic vertical packaging solution for the dairy industry, a reliable sauce packaging machine for condiments, or a cost-effective liquid soap packaging machine for personal care products, its customizable filling systems adapt to any task. This versatility ensures that from milk and juice to detergents and oils, your product is handled with the utmost care and precision.

Bag Type

While the YL400A excels at producing the cost-effective pillow pouch shown here, its flexibility extends to creating other popular bag styles. The system can be configured to produce stand-up gusseted bags for better shelf presence, or small-format sachets for single-serving portions of sauces or shampoo. Regardless of the style, our advanced sealing technology ensures every bag, whether made from laminated or PE film, has a strong, leak-proof seal you can trust.

Competitive Advantage

- Purpose-Built for Liquids, Not Adapted

While many VFFS machines are modified powder packers, the YL400A is engineered from the ground up as a purpose-built liquid packer. This fundamental difference results in superior dosing precision for everything from water-thin beverages to viscous pastes, and unmatched sealing reliability that generic machines cannot offer.

- Zero-Tolerance for Leaks and Contamination

Competitors often struggle with seal contamination when packing oils or sauces. The YL40A eliminates this issue with its advanced anti-drip filling nozzles and a multi-stage sealing process. This guarantees the clean, strong seals required for professional hygienic packaging, protecting your product and brand reputation.

- Maximize Uptime with Faster Cleaning & Changeovers

Downtime is lost revenue. Our design features quick-release liquid contact parts and full CIP (Clean-in-Place) compatibility. This enables rapid, tool-free cleaning and quick changeovers between different products, significantly boosting your overall operational efficiency compared to machines requiring extensive manual cleaning.

Why Choose Soontrue?

Soontrue has decades of experience in liquid and paste packaging solutions, delivering machines that combine efficiency, precision, and hygiene compliance. The YL400A Liquid Vertical Packaging Machine is backed by Soontrue’s global support network, helping buyers achieve higher productivity and lower operational risks.

FAQ - YL400A Liquid Vertical Packaging Machine

Q1: What types of liquids can the YL400A handle?

A1: The machine can pack water-like beverages, sauces, dairy products, oils, and personal care liquids, with options for both thin and thick viscosities.

Q2: How does it ensure leak-proof sealing?

A2: The YL400A uses servo-controlled heat sealing with precise temperature control, ensuring strong and reliable seals that prevent leakage.

Q3: Can the YL400A switch between different liquids easily?

A3: Yes. With quick-cleaning filling systems, it can changeover between products in a short time, making it suitable for multi-product production lines.

Q4: What pouch types are supported?

A4: It can form and fill pillow bags, gusset bags, and sachets directly from film rolls, using laminated or PE films.

Q5: What is the typical output speed?

A5: Depending on liquid type and bag size, the YL400A can reach 20 bags per minute, balancing speed and accuracy.

Q6: Does Soontrue provide installation and training?

A6: Yes. Soontrue offers on-site installation, operator training, and remote technical support to ensure smooth operation.