Collaborative Palletizing Robots: Revolutionizing the Palletizing Process

Industry news

Introduction: The Future of Palletizing

In today’s competitive manufacturing landscape, businesses are increasingly turning to automation to optimize their production lines. One such breakthrough in automation is the use of robot palletizers. These systems are not only more efficient but also more flexible than conventional palletizing methods. In this article, we’ll explore what is a robot palletizer, the differences between conventional vs robotic palletizing, delve into how palletizing robots work, and address frequently asked questions about their applications in industries like food processing.

1. What is a Robot Palletizer?

A robot palletizer is an automated machine designed to stack products onto pallets in a precise and efficient manner. Unlike traditional mechanical systems or manual labor, robot palletizers use robotic arms and advanced vision systems to handle, orient, and place items on pallets. These machines offer significant advantages in terms of flexibility, speed, and accuracy, making them ideal for various industries, including food processing, pharmaceuticals, and manufacturing.

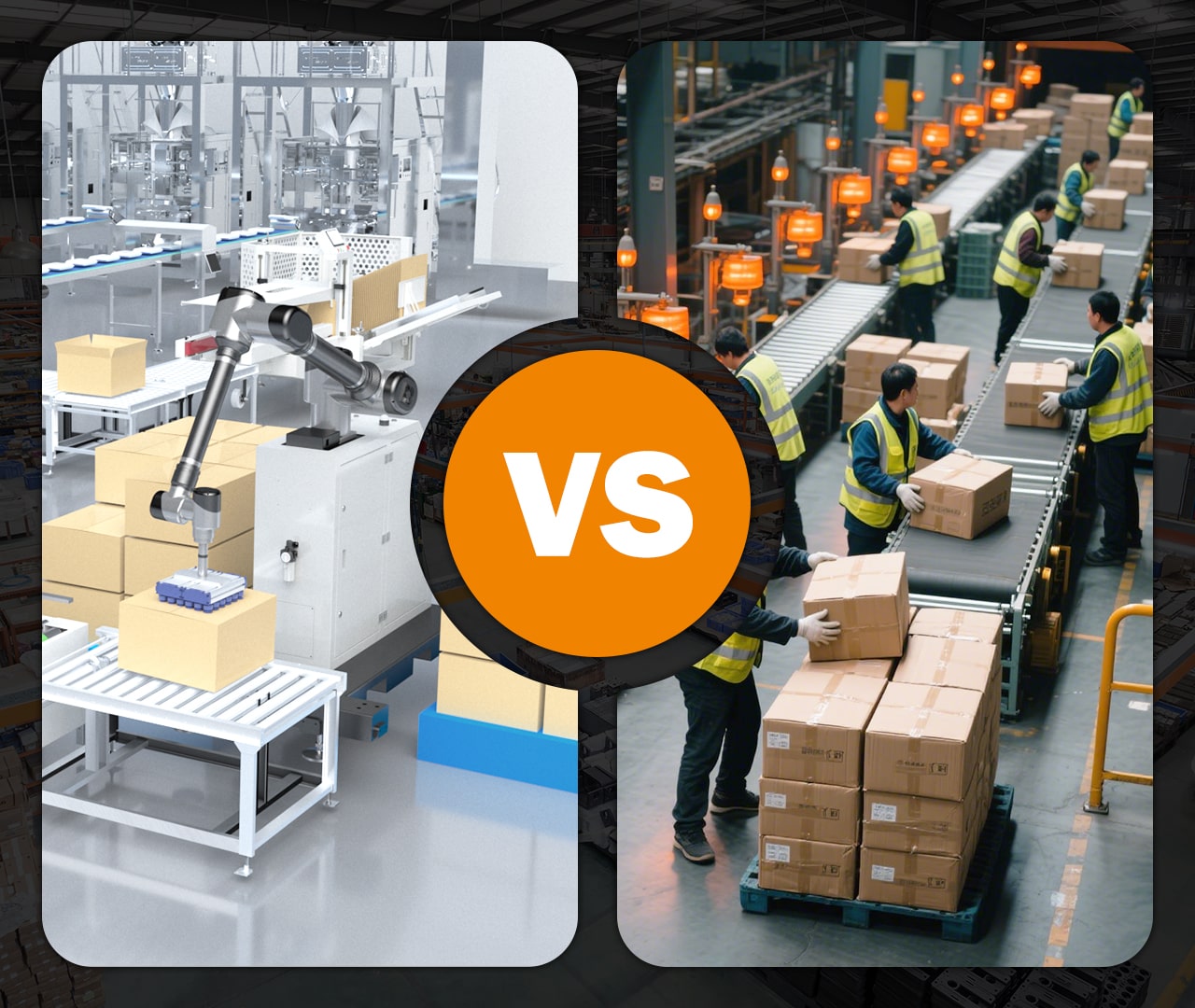

2. Conventional vs Robotic Palletizing: A Comparison

Conventional palletizing has been the standard for many years, relying heavily on human labor or mechanical systems like conveyors. These systems often involve workers manually stacking boxes or using fixed machines to handle the load. While these methods can be effective, they have several limitations:

- Labor Intensive: Requires significant human input, leading to higher labor costs.

- Less Flexibility: Fixed machines can only handle a specific type of load and require frequent reconfiguration for different products.

- Space-Consuming: Older machines often take up more space and may not be easy to integrate into existing lines.

On the other hand, robotic palletizing systems are far more efficient and versatile:

- Automated: No need for manual labor, reducing the risk of human error and improving safety.

- Adaptable: Robotic systems can handle various load sizes, products, and palletizing patterns, making them ideal for industries with diverse production lines.

- Space-Efficient: These robots are compact and can be integrated seamlessly into existing production lines.

3. How Do Palletizing Robots Work?

Palletizing robots are highly sophisticated machines that use a combination of hardware and software to automate the process of stacking products onto pallets. Here's how they work:

- Grippers and Arms: Robots use specialized grippers or suction cups to pick up products from conveyors or other machines.

- Vision Systems: Many palletizing robots are equipped with vision systems that allow them to recognize objects, adjust their grip, and place them accurately on the pallet.

- Movement: Using robotic arms, these systems can move products to precise locations, stacking them in various patterns depending on the required palletizing configuration.

- Software: Palletizing robots are programmed with advanced software that allows them to adapt to different products, pallet sizes, and production speeds.

4. Palletizing Systems for the Food Industry

The food industry, which often deals with high-volume production and delicate products, benefits significantly from robotic palletizing systems. These systems are particularly useful for:

- Handling fragile or irregularly shaped items: Palletizing robots can adapt their movements to handle sensitive food packaging without damaging the product.

- Maintaining hygiene standards: Robots can be equipped with easy-to-clean surfaces and can work in environments that adhere to strict food safety regulations.

- Increased speed and efficiency: Robots can work 24/7, improving throughput and reducing production costs in food processing facilities.

In addition, robotic palletizing systems can integrate seamlessly with other automated systems like sorting and packaging, enhancing overall production efficiency.

5. How Much Does a Robotic Palletizer Cost?

The cost of a robotic palletizer can vary widely depending on several factors, including:

- Type of robot: Collaborative robots tend to be more affordable than larger industrial robots, as they are designed for flexibility and ease of use.

- Payload capacity: The heavier the payload capacity, the more expensive the system may be.

- Customization: Customized robotic palletizing systems tailored to specific production lines or product types tend to have a higher price tag.

- Integration with other systems: If the robot is integrated with other equipment like conveyors, stretch wrappers, or vision systems, this will add to the cost.

On average, a basic robotic palletizer may cost anywhere from $25,000 to $100,000, with high-end systems reaching even higher prices depending on the features and capabilities required.

6. What is Layer Palletizing?

Layer palletizing refers to the process of stacking products in layers rather than individually. This is particularly useful when dealing with uniform items like boxes, bags, or containers that need to be stacked efficiently and securely. Layer palletizing robots are equipped to:

- Pick up multiple items at once: These robots can grab entire layers of products, significantly improving speed and reducing handling time.

- Create stable, even layers: This ensures that the pallet is balanced and maximizes the number of products per pallet, improving space efficiency during storage and transportation.

Layer palletizing is especially popular in industries like food and beverage, where high-volume, uniform products like cans or boxes need to be palletized quickly and securely.

Conclusion: Embrace Automation with Robotic Palletizing

As the demand for speed, efficiency, and accuracy continues to rise in industries such as food production and manufacturing, robotic palletizing systems are becoming essential tools for businesses looking to stay competitive. These systems provide significant advantages over conventional methods, including flexibility, reduced labor costs, and the ability to handle various product types.

For those considering automation, investing in a robotic palletizer offers long-term savings and operational improvements. If you're ready to upgrade your palletizing system, contact us today to learn more about our collaborative palletizing robots and discover how they can optimize your production line.