Comprehensive Guide to Pillow Packing Machine: Selection & Application Scenarios

Industry news

Boost Your Packaging Efficiency with Pillow Packing Solutions

In today's fast-paced manufacturing landscape, businesses often face significant challenges: high labor costs, inconsistent packaging quality, and low production efficiency. The pillow packing machine, also known as the horizontal flow wrapper, emerges as a game-changer by streamlining packaging processes, reducing costs, and ensuring stable product quality. In this article, we'll thoroughly explore pillow packing machine types, their applications, and key factors in selecting the ideal solution for your business.

1. What Is a Pillow Packing Machine? Working Principle and Advantages

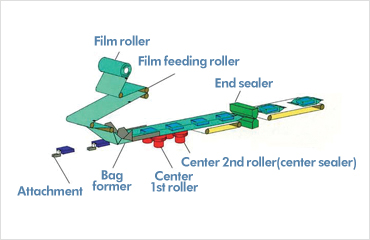

A pillow packing machine, or horizontal flow wrapper, is automated equipment used primarily for packaging items horizontally. Products are fed via conveyors into the packaging machine, where the film wraps around them, forming a tight seal on three sides. The sealed product is then cut to length and output as a fully packaged item.

Key Advantages:

- High Speed & Efficiency: Capable of packing hundreds of items per minute.

- Versatile Packaging Range: Suitable for various product sizes and shapes.

- Attractive & Secure Packaging: Ensures consistent, neat, and reliable sealing.

- Automation: Reduces labor costs significantly through automated operations.

- Easy Maintenance: User-friendly designs, intuitive interfaces, and minimal downtime.

2. Types of Pillow Packing Machines: Rotary vs. Box Motion

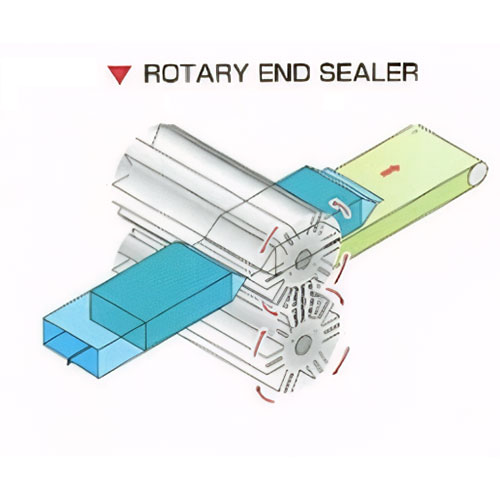

Rotary Pillow Packing Machine (Continuous Motion)

Working Principle:

Continuous motion technology enables seamless product handling, making rotary pillow packers ideal for high-speed packaging lines.

Advantages:

- Faster Production Speeds: Excellent for mass production environments.

- Stable and Reliable: Ideal for uniform-sized products like snacks, biscuits, and candies.

Considerations:

Less flexible for irregular product shapes; primarily designed for standardized products.

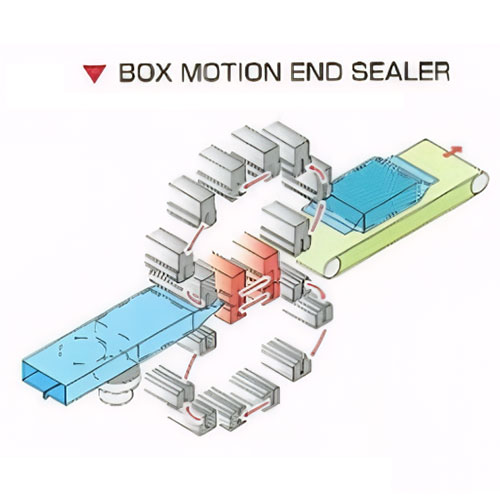

Box Motion Pillow Packing Machine (Intermittent Motion)

Working Principle:

Operates with an intermittent motion, stopping briefly to seal each package, offering superior sealing precision.

Advantages:

- Superior Sealing Quality: Especially suitable for products requiring airtight seals (e.g., medical supplies).

- Flexible Packaging Options: Handles varying product dimensions effortlessly.

- Easy to Maintain & Adjust: Simpler mechanical structure.

Considerations:

Slightly lower packaging speeds compared to rotary machines.

Choosing the Right Machine:

- For standardized products and large-scale operations → Rotary Pillow Packing Machine.

- For smaller runs, varied sizes, and tighter sealing needs → Box Motion Pillow Packing Machine.

3. Industry-Specific Application Scenarios

Food Industry Applications

Pillow packers excel in food packaging, from bakery items to snacks, confectionery, instant noodles, and frozen foods. Soontrue's horizontal flow wrappers are engineered specifically to enhance product freshness, shelf life, and visual appeal, ensuring hygienic and attractive packages.

Example: Soontrue rotary wrappers efficiently package biscuits, whereas box motion wrappers ensure airtight seals for specialty snacks.

Pharmaceutical Industry Applications

Pharmaceutical products demand meticulous packaging standards, including tight sealing, contamination prevention, and GMP compliance. Pillow packing machines, particularly box motion models, meet these stringent requirements.

Example: Soontrue flow wrappers provide precise packaging solutions for capsules, masks, and medical instruments, ensuring product integrity and safety.

Industrial Products Packaging

Industrial components require protection against moisture, dust, and damage. Pillow packing machines offer a reliable solution for items like hardware parts, electronics, and everyday industrial tools.

Example: Soontrue pillow wrappers effectively protect small electronic parts, counting accurately and packaging securely.

Other Potential Industries

Beyond these applications, horizontal flow wrappers also find use in cosmetics, agriculture, and daily consumer goods industries.

4. Key Technologies & Future Trends

Modern pillow packing machine leverage advanced technologies like servo motors, PLC controls, photoelectric tracking, and user-friendly interfaces.

Future Development Trends:

- Increased automation and intelligence for streamlined operations.

- Flexible packaging format adjustments for quick product changeovers.

- Environmentally friendly packaging materials integration.

- Enhanced integration capabilities with upstream and downstream machinery.

5. Selecting a Trusted Pillow Packing Machine Supplier

Choosing the right equipment supplier is crucial for long-term success:

- Evaluate supplier experience and market reputation.

- Examine technical specifications and machine capabilities.

- Consider customer feedback and after-sales support quality.

- Conduct onsite visits and hands-on demonstrations.

(Soontrue is a reliable partner, offering robust after-sales service and advanced, tailor-made packaging solutions.)

6. Conclusion & Outlook

Pillow packing machines are indispensable in modern packaging workflows, improving efficiency, reducing costs, and enhancing product quality. By carefully choosing the right type and partner, businesses can significantly upgrade their packaging lines.

At Soontrue, we’re committed to innovation and providing custom solutions to help you achieve packaging excellence.

📩 Ready to upgrade your packaging line? Contact Soontrue today and let's discuss your customized solution!

FAQ (Frequently Asked Questions):

Q: What’s the difference between rotary and box motion pillow packing machine?

A: Rotary machines operate continuously at higher speeds ideal for uniform products. Box motion machines intermittently pause for precise sealing, suitable for variable-sized or airtight packaging requirements.

Q: How do I choose the right pillow packing machine for my product?

A: Consider factors like product uniformity, production volume, sealing precision requirements, and your budget constraints. Soontrue can guide you through these decisions.

Q: Are pillow packing machines suitable for small businesses?

A: Absolutely. Pillow packing machines offer cost-effective, automated solutions beneficial even for small-scale operations, significantly reducing manual labor.

Q: How can pillow packing machines reduce overall packaging costs?

A: They enhance productivity, reduce waste through precise sealing, decrease labor expenses, and minimize downtime with reliable, easy-to-maintain designs.