Automated Flow Packaging Solution

Automated Flow Packaging Solution Typical Applications

- Bakery & Confectionery: Biscuits, cookies, cakes, chocolate bars

- Snacks & Convenience Foods: Instant noodles, energy bars, candies

- Frozen Foods: Dumplings, spring rolls, meat products

- Household & Industrial Products: Medical supplies, small hardware, consumer goods

An Automated Flow Packaging Solution is a complete packaging system built around a flow packing machine (also called a pillow packing machine). It is designed to wrap products in pillow-shaped packs and seamlessly connect them to secondary and end-of-line automation such as case erecting, case packing, and palletizing.

Think of it as a "continuous packaging conveyor" :

- Products are automatically fed onto a belt.

- They are wrapped tightly in film, sealed, and cut into individual pillow packs.

- The flow-wrapped packs are then transferred directly to secondary packaging for grouping, cartoning, and palletizing.

Why It Matters

- This solution is ideal for manufacturers who need high-speed, versatile, and cost-efficient packaging. It provides:

- Flexibility: Can package a wide range of food and non-food products.

- Consistency: Every pack is sealed airtight, protecting freshness and presentation.

- Scalability: Easily integrates with end-of-line systems for complete automation.

How It Works

- Product Feeding – Products are placed on the infeed conveyor, either manually or via automatic feeding systems.

- Wrapping – Film is wrapped around the product as it travels forward.

- Sealing & Cutting – Heat-sealing jaws seal the film lengthwise and crosswise, then cut the film to create individual pillow packs.

- Discharge – Finished packs exit the flow wrapper, ready for further handling.

- End-of-Line Packaging – Packs are automatically grouped, loaded into cartons, sealed, and stacked on pallets.

👉 In short, this solution turns loose or individual items into finished, retail-ready packs and delivers them directly to pallet-ready cartons—all in one automated process.

Machine Parameters

Key Features

Customizable flow packing system: Our flow packing machine can be tailored to fit specific product sizes, shapes, and production needs, making it versatile for a wide range of industries.

High-speed operation: Ensures that products are packed quickly and efficiently, maintaining high throughput without compromising quality.

End-of-line packaging integration: The flow packing machine is seamlessly connected with the downstream packaging processes, such as case erecting, case packing, and palletizing, providing a fully automated solution.

Precise product handling: The machine's advanced conveyor and feeding systems ensure that products are placed and wrapped accurately with minimal waste.

Adaptable for various products: Whether you’re packaging single-piece or multi-piece products, the system can handle a wide range of items including snacks, confectionery, bakery products, and more.

Application

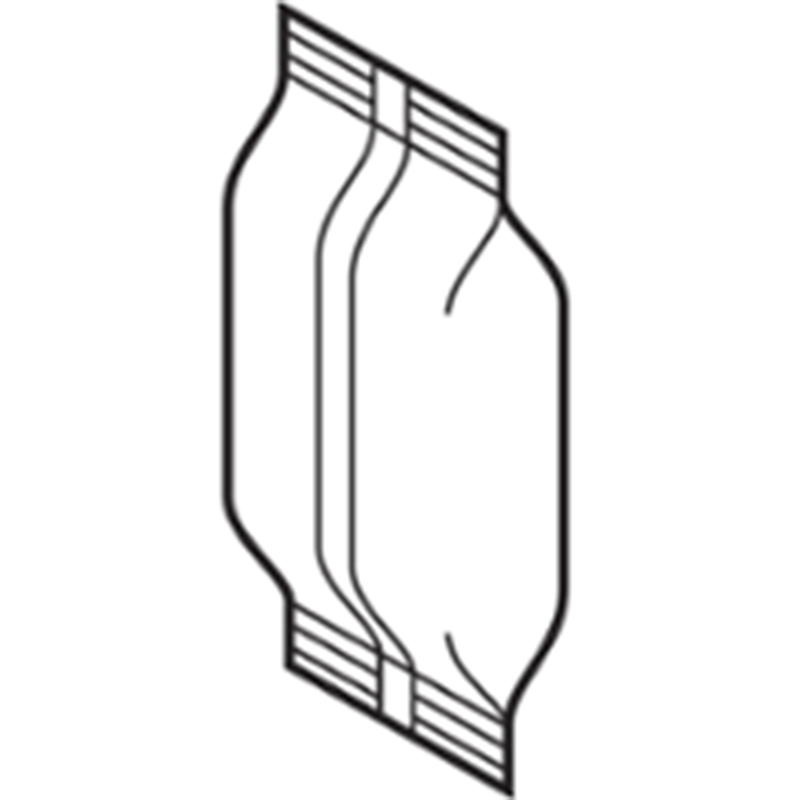

Bag Type

Competitive Advantage

Unlike conventional packaging setups that rely on manual product feeding and separate equipment, Soontrue's Automated Flow Packaging Solution provides end-to-end integration. With advanced feeding technology, smart sensors, and high-speed flow wrappers, our solution ensures fewer errors, faster throughput, and better product presentation. The system supports multi-piece or chain packs, which many competitors cannot offer efficiently. Backed by our global service network, Soontrue delivers a packaging line that is faster, more adaptable, and more reliable than standard market alternatives.

Why Choose Soontrue?

With over 30 years in packaging automation, Soontrue has become a global leader in flow packaging technology. Our pillow packing machines are trusted by top food and consumer goods brands worldwide. We provide tailored systems that combine primary packaging (flow wrapping) with secondary automation (case packing and palletizing), ensuring maximum efficiency. Supported by a global service team and proven engineering expertise, Soontrue guarantees reliable installation, long-term performance, and ongoing technical support.

FAQ About Automated Flow Packaging Solution

Q1: Can one line handle both small and large products?

Yes. Our flow packaging machines can be configured with adjustable forming boxes and sealing jaws, allowing quick changeovers between different product sizes.

Q2: What if my products are fragile or irregular in shape?

We offer customized feeding systems—such as aligners, pushers, or robotic feeders—that gently handle fragile items like biscuits or irregular products without causing damage.

Q3: Is pillow packing only for single products, or can it do multipacks?

Our machines can handle both single-item packs and multi-piece packs (e.g., 2-in-1, 5-in-1 chain packs), giving you maximum flexibility for retail and wholesale.

Q4: How do you ensure sealing quality at high speed?

Servo-driven sealing jaws and temperature-controlled systems ensure every pack is airtight and consistent, even at maximum speeds.

Q5: Will integration with end-of-line systems slow down production?

No. Integration reduces manual handling and eliminates bottlenecks. Case packing and palletizing modules are synchronized with the flow wrapper to maintain continuous production.

Q6: What is the typical lead time for delivery?

Usually 60–90 days depending on machine configuration. For urgent projects, phased delivery can be arranged.

Q7: How reliable is after-sales service?

Soontrue offers a global support network, with local spare parts depots, overseas engineers, and 24/7 online support to minimize downtime.