Automated packaging solution tailored to industry-specific requirements for frozen dumpling

Automated Frozen Dumplings Packaging Solution Typical Applications

- Frozen Dumplings & Dim Sum: Jiaozi, gyoza, wontons, shumai

- Other Frozen Foods: Tangyuan, baozi, frozen buns, meat dumplings

- Ready-to-Eat Frozen Meals: Noodles with dumplings, combo packs

- Industrial Frozen Food Lines: Dumpling production lines, cold-chain packaging lines

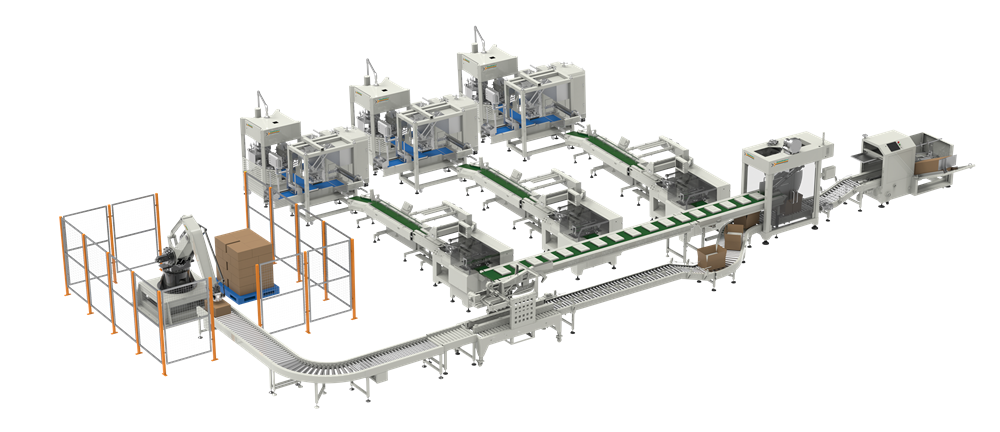

An Automated Packaging Solution for Frozen Dumplings is a fully customized system designed to integrate seamlessly with dumpling machines and frozen food production lines. Unlike general-purpose packaging equipment, this solution is built specifically for frozen dumplings and similar products that require gentle handling, moisture protection, and cold-chain compatibility.

Think of it as the final stage of your dumpling production line:

- Freshly formed dumplings from the dumpling machine are sorted, aligned, and portioned.

- They are packed into pillow bags, trays, or pouches with strong sealing to prevent freezer burn.

- Secondary packaging groups the primary packs into cartons.

- Finally, cartons are palletized for cold storage or shipment.

Why It Matters

- Cold-Chain Ready – Ensures dumplings remain intact, fresh, and free from freezer burn.

- Integration with Dumpling Machines – Directly connects to upstream forming lines for continuous automation.

- Flexibility – Supports different pack sizes, from single-serve bags to family-size cartons.

- Efficiency – Reduces labor in frozen food plants while increasing throughput and consistency.

How It Works

- Feeding & Sorting – Dumplings from the forming line are transferred onto conveyors; automatic aligners prepare them for packaging.

- Primary Packaging – Flow packing machines or VFFS machines pack dumplings into bags or pouches. Optional nitrogen flushing helps preserve freshness.

- Freezing Compatibility – Sealing strength and packaging film are selected to withstand frozen storage conditions.

- Secondary Packaging – Bagged dumplings are automatically loaded into cartons.

- End-of-Line Automation – Cartons are sealed, labeled, and stacked on pallets ready for cold-chain logistics.

👉 In short, Soontrue’s solution ensures that dumplings go from forming to frozen storage in one continuous, automated process.

Machine Parameters

Key Features

Integrated Dumpling Production and Packaging: Starting with a dumpling production machine, the automated line includes precise shaping, filling, and forming for consistent, high-quality dumplings before they enter the packaging line.

Optimized Frozen Product Handling: This system is designed for frozen dumplings, with specially calibrated conveyors and feeding systems to prevent product breakage or thawing, maintaining the integrity and appearance of each dumpling.

Flexible Primary Packaging Options: Compatible with vertical bagging machines and premade pouch systems, this solution offers flexibility in packaging styles, from pillow packs to stand-up pouches, catering to consumer preferences and brand requirements.

Secondary Packaging Integration: Once the dumplings are packaged in primary bags, they are seamlessly transferred to the secondary packaging systems, including case erecting, case packing, and palletizing, providing an efficient, one-stop solution.

Hygienic, Food-Grade Design: Built with food-grade stainless steel and easy-to-clean surfaces, the system meets stringent hygiene standards essential for frozen food processing and packaging, ensuring both product safety and quality.

Application

Bag Type

Competitive Advantage

Unlike generic packaging lines, Soontrue's solution is tailored to the frozen dumpling industry. By combining dumpling forming machines with automated flow wrapping and end-of-line systems, we deliver a turnkey cold-chain packaging line. Compared with other suppliers:

- Higher Compatibility – Fully integrated with dumpling machines.

- Better Seal Strength – Packaging film and sealing designed to withstand freezing.

- Flexibility – Supports single packs, family-size bags, and retail cartons.

- Lower Downtime – Quick-change systems reduce delays between product runs.

- Global Experience – Installed solutions in frozen food factories worldwide.

Why Choose Soontrue?

With more than 30 years in packaging automation and proven expertise in dumpling and frozen food production lines, Soontrue is a trusted partner for leading food manufacturers. We combine dumpling forming technology with advanced packaging systems, providing complete end-to-end automation.

Choosing Soontrue means:

- Industry-Specific Expertise – Deep knowledge of frozen food packaging challenges.

- Tailored Engineering – Systems built to match your dumpling line and cold-chain needs.

- Global Service – Engineers, spare parts, and 24/7 support worldwide.

- Long-Term Value – Reliable equipment with faster ROI for frozen food plants.

FAQ About Automated Frozen Dumplings Packaging Solution

Q1: Can the packaging line connect directly to my dumpling machine?

Yes. Our system is designed to integrate seamlessly with dumpling forming machines, ensuring a continuous production-to-packaging workflow.

Q2: Will the packaging protect dumplings from freezer burn?

Yes. Strong sealing, high-quality films, and optional nitrogen flushing keep dumplings fresh and protected during cold storage.

Q3: Can the same line handle different pack sizes?

Yes. Quick-change systems allow fast switching between small single-serve packs and large family-size packs.

Q4: Are frozen dumplings too fragile for high-speed packaging?

No. Our feeders and conveyors are designed for gentle handling, preventing damage to dumpling skins while maintaining high output.

Q5: How does this reduce labor costs in frozen food plants?

Automation replaces manual bagging and cartoning, reducing reliance on labor and minimizing errors.

Q6: What’s the lead time for delivery?

Typically 60–90 days, depending on customization and system scale.

Q7: What about after-sales service and spare parts?

Soontrue provides global support, including overseas engineers, spare parts depots, operator training, and 24/7 technical assistance.