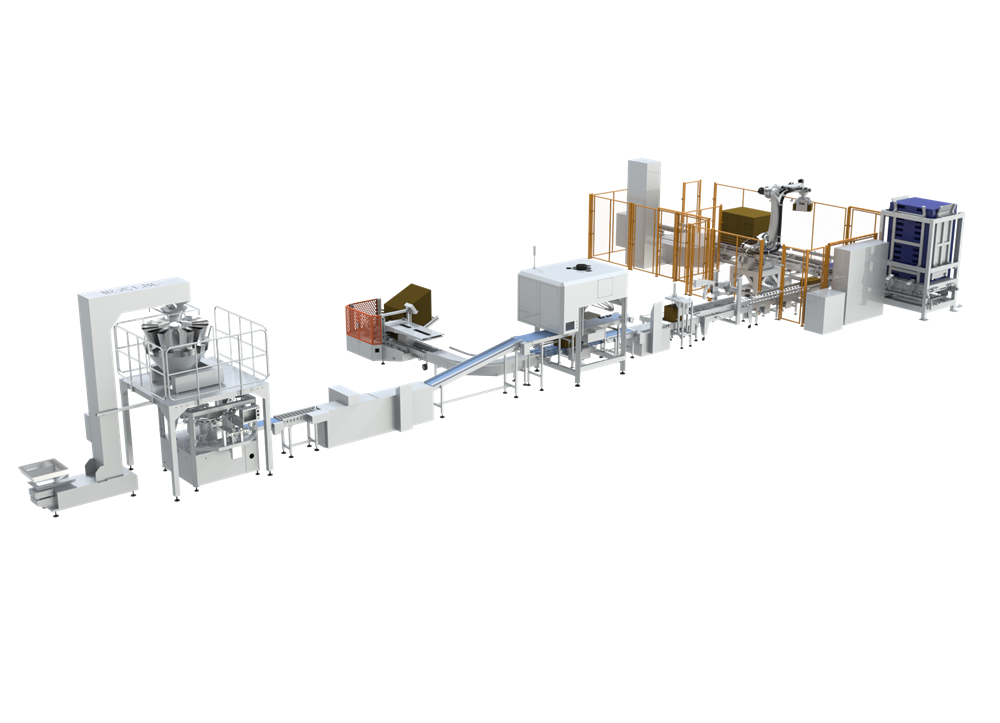

Soontrue provides end-to-end frozen food packaging solutions:

- Primary Packaging

- Frozen products packaging machines for dumplings, buns, and seafood.

- IQF packaging machines for shrimp, berries, and mixed vegetables.

- Vertical form-fill-seal (VFFS) machines for pillow bags of frozen items.

- Premade pouch machines for zipper and stand-up pouches.

- Secondary Packaging

- Carton systems for grouping retail pouches or pillow packs.

- Case packers & sealers for bulk transport.

- Robotic palletizers for cold-chain and export-ready shipments.

Why Choose Soontrue for Frozen Food Packaging Solutions?

- Specialized IQF packaging solutions for portion-controlled frozen foods.

- Cold-chain ready designs preventing sealing and film cracking issues.

- Moisture-proof packaging films for long-term storage.

- Flexible pack formats from sachets to large export bags.

- Complete automation for both primary and secondary packaging.

Customer Cases

- A dumpling manufacturer integrated Soontrue's IQF packaging line, packaging frozen dumplings into 500g pillow bags.

- A seafood processor adopted premade pouch machines for frozen shrimp export packs.

- A vegetable exporter used VFFS + palletizers for IQF mixed vegetables in 1kg retail bags and 20kg bulk cartons.

FAQ About Frozen Food Packaging Solutions

Q1: What is IQF packaging?

A: Individual Quick Freezing (IQF) packaging refers to portioning and packing individually frozen items like shrimp, berries, or dumplings.

Q2: What machines are used for frozen dumplings?

A: Soontrue provides frozen product packaging machines and VFFS pillow pack machines for dumplings.

Q3: Can your machines handle both seafood and vegetables?

A: Yes. Our IQF packaging solutions adapt to shrimp, fish, berries, and vegetables.

Q4: How do you ensure packaging quality in frozen environments?

A: By using cold-chain compatible sealing systems and frost-resistant films.

Q5: Do you provide secondary packaging for frozen food exports?

A: Yes. Soontrue offers carton, case packing, and palletizing solutions.