Automated Vertical Packaging Solution

Automated Vertical Packaging Solution Typical Applications

Food Industry: Rice, beans, flour, milk powder, spices, snacks, frozen foods

Pharmaceuticals: Powders, granules, capsules, tablets

Chemicals & Industrial: Fertilizers, detergents, plastic granules

Liquids & Pastes: Sauces, condiments, dairy products

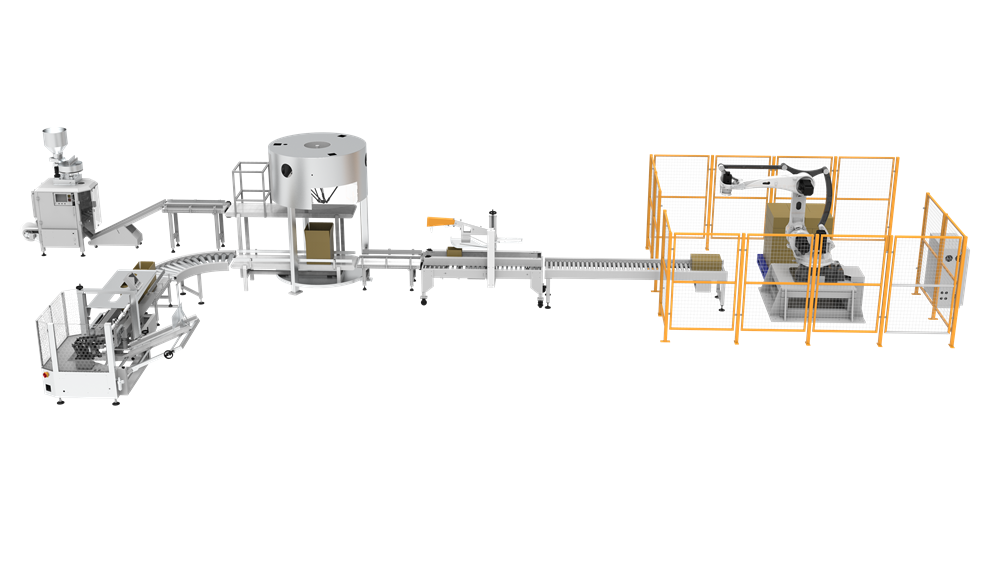

An Automated Vertical Packaging Solution is a complete packaging system built around the Vertical Form Fill Seal (VFFS) machine, which is the core equipment for primary packaging. Unlike using separate machines that only pack products into bags, this solution connects the VFFS machine with secondary and end-of-line systems such as case packing and palletizing, creating a fully automated workflow from raw product to pallet-ready cartons.

Think of it as a "packaging highway" :

- Products enter at one end (powders, granules, liquids, or solids).

- They are measured, filled, and sealed into bags or pouches by the VFFS machine.

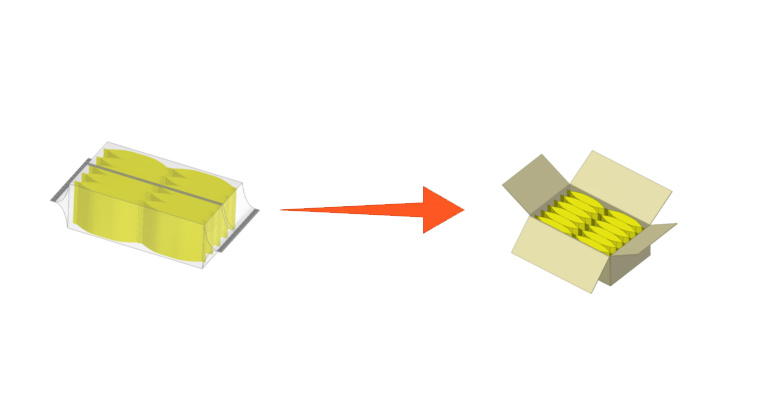

- The finished bags then move automatically to secondary packaging (cartons, trays).

- Finally, the cartons are sealed and stacked on pallets, ready for storage or shipping.

Why It Matters

This solution is ideal for manufacturers who want to:

- Handle high volumes with minimal downtime.

- Reduce dependence on manual labor.

- Ensure precision and consistency in every package.

- Adapt quickly to different product types and packaging formats.

How It Works

- Film Feeding & Forming – A roll of film is pulled into the VFFS machine and formed into a tube.

- Product Filling – The product is dispensed into the tube by auger fillers (for powders), volumetric cups (for granules), or pumps (for liquids).

- Sealing & Cutting – The tube is sealed vertically and horizontally, then cut to form individual bags.

- Secondary Packaging – Finished bags are automatically grouped and loaded into cartons or trays.

- End-of-Line Automation – Cartons are sealed, labeled, and stacked on pallets for delivery.

👉 In short, an Automated Vertical Packaging Solution turns loose products into ready-to-ship packages, all in one streamlined, fully automated process.

Machine Parameters

Key Features

- Custom-built vertical packing machine: Our vertical packing machines can be tailored to handle specific product types, sizes, and packaging materials. These machines are ideal for packaging products in pouches, bags, or sachets.

- High-speed, continuous operation: Capable of high-speed filling and sealing, the machine increases production output while maintaining consistency and quality.

- Seamless integration with end-of-line packaging: The system combines primary packaging with automated downstream processes such as case erecting, case packing, and palletizing, offering a fully automated packaging line.

- Precision filling technology: The VFFS machine ensures accurate product filling, reducing waste and ensuring that each pack contains the correct product quantity.

- Versatile packaging options: This system can handle a variety of products, including powders, granules, liquids, and more, making it ideal for food, pharmaceuticals, and consumer goods.

Application

-

Biscuit & Cookie Packaging Solutions

-

Bread & Bakery Packaging Solution

-

Chocolate Packaging Solutions

-

Noodle Packing Solutions

-

Coffee Powder Packaging Solutions

-

Nuts Packaging Solutions

-

Oil Packaging Solutions

-

Candy Packaging Solutions

-

Dried Fruits Packaging Solutions

-

Puffed Food Packaging Solutions

-

Detergent Powder Packaging Solutions

-

Other Powder Packaging Solutions

-

Seasoning Powder Packaging Solutions

-

Pet Food Packaging Solutions

-

Medical Supplies Sterile Packaging Solutions

-

Personal Care Liquid Packaging Solutions

-

Sauce Packaging Solutions

-

Beverage Packaging Solutions

-

Secondary Packaging (Random Bag Packaging Solutions)

-

Carton & Box Secondary Packaging Solutions

Bag Type

Competitive Advantage

Unlike suppliers that provide only a standalone VFFS machine, Soontrue offers a complete automated vertical packaging solution that integrates both primary and secondary packaging. This means customers benefit from fewer bottlenecks, faster production speed, and greater consistency. Our system is not limited to standard formats—it is tailor-made for each production line, ensuring compatibility with existing processes. With servo-driven controls, IoT-enabled monitoring, and a proven global service network, Soontrue’s solution delivers superior efficiency and reliability compared to conventional setups.

Why Choose Soontrue?

Soontrue has over 30 years of experience in packaging automation and has become a trusted partner for leading global manufacturers. We specialize in designing tailored vertical packaging systems that combine advanced technology, flexible configurations, and world-class service. With expertise across multiple industries and a strong global support network, we ensure that each system is delivered with precision, reliability, and long-term performance. Choosing Soontrue means choosing a partner that will help you achieve greater efficiency, lower costs, and higher market competitiveness.

FAQ About Automated Vertical Packaging Solution

Q1: Can the system handle different types of products without frequent changeovers?

Yes. The VFFS machine can be equipped with different filling systems—auger fillers for powders, volumetric cups for granules, and pumps for liquids or pastes. Changeovers are designed to be quick, minimizing downtime and maximizing production flexibility.

Q2: What packaging formats are supported?

Our solution supports pillow bags, gusseted bags, stand-up pouches, and even large bulk bags.

Q3: Will integrating the whole line increase the risk of breakdowns or downtime?

On the contrary, full integration reduces bottlenecks and coordination issues between separate machines. The system includes intelligent monitoring and fault diagnosis, so operators can quickly identify and solve issues, reducing downtime and protecting production schedules.

Q4: How does this solution reduce operational costs?

By automating both primary and secondary packaging, the system significantly reduces reliance on manual labor. Accurate filling minimizes product waste, and automated end-of-line handling lowers logistics errors, saving costs in both manpower and materials.

Q5: What about after-sales support and spare parts availability?

Soontrue has a global service network with overseas engineers and local spare parts depots. We provide on-site training, remote technical assistance, and fast-response service to ensure that your line keeps running smoothly with minimal disruption.

Q6: How long is the delivery time for a customized vertical packaging solution?

Typically 60–90 days, depending on the level of customization and capacity required. For urgent projects, we can adjust production schedules and provide phased delivery to help customers meet market deadlines.

Q7: Is the system future-proof if my production needs grow?

Yes. The modular design allows additional functions—such as cartoning, case packing, or palletizing—to be added later. This ensures your investment remains scalable and adaptable as your business expands.