Vertical Packing Line

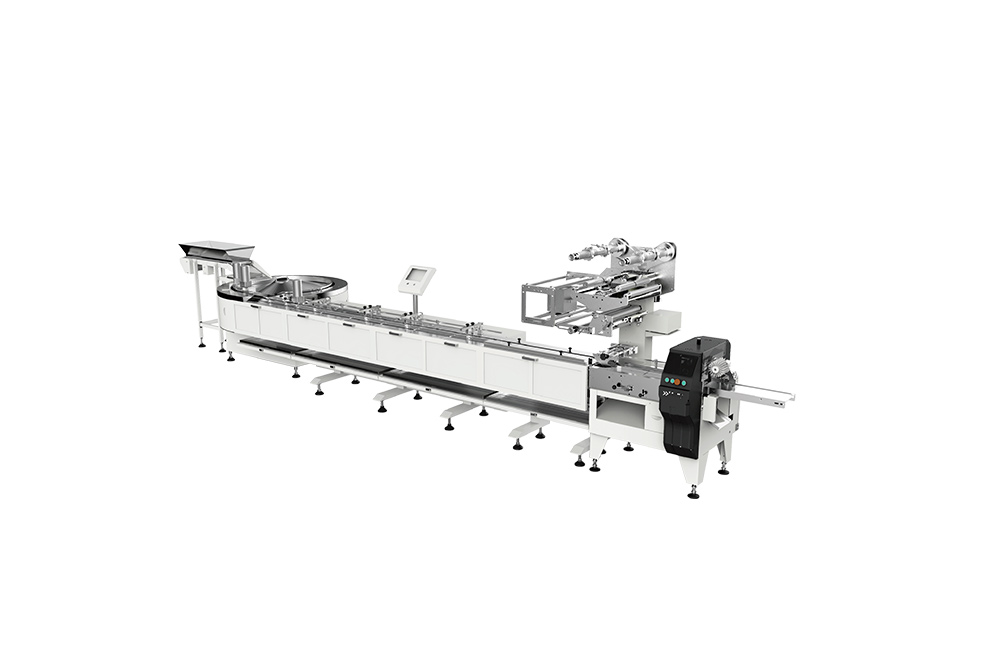

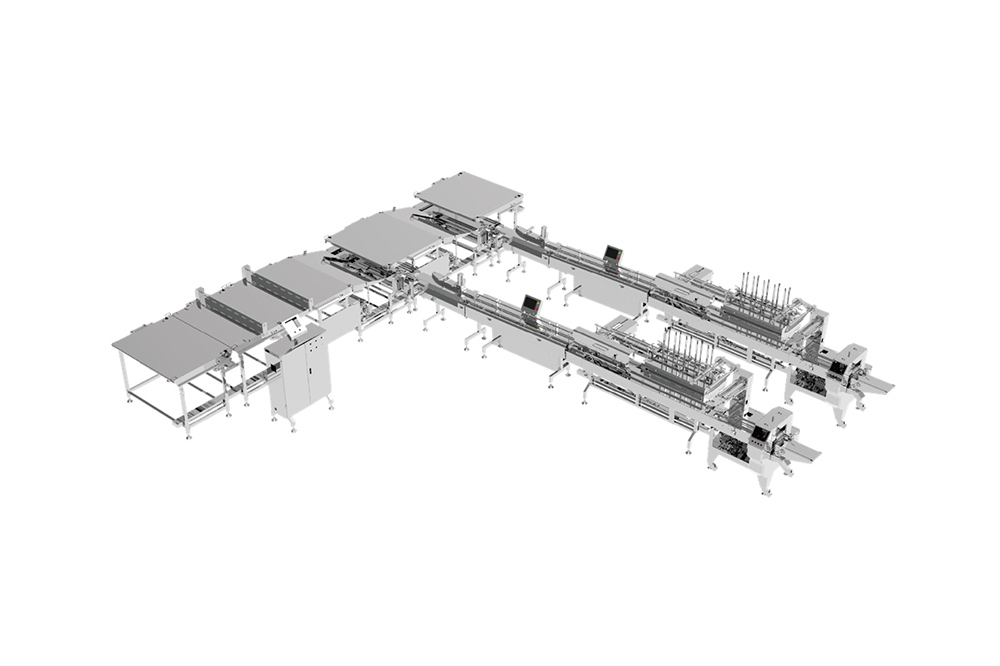

Puffed food packaging solutions are designed to protect fragile snack products such as chips, popcorn, and extruded snacks from breakage, moisture, and staleness. Unlike dense foods, puffed snacks are lightweight and bulky, requiring packaging that maintains product integrity and extends shelf life. Automated snack packaging machines deliver versatile formats including pillow packs, gusseted bags, stand-up pouches, and family-size packs, ensuring convenience and retail appeal.

🎥 Watch how Soontrue machines package puffed foods in pillow bags, gusseted packs, stand-up pouches, and multipacks. Demonstrations include chips, popcorn, and extruded corn snacks at high speeds.

The puffed food industry faces several key challenges:

Soontrue provides advanced puffed food packaging solutions tailored for snacks:

Q1: What is the most common packaging for puffed foods?

A: Pillow bags with nitrogen flushing are the most common, offering protection and freshness.

Q2: Can puffed snacks be packed in stand-up pouches?

A: Yes. Premade pouch packaging machines are widely used for premium retail packaging of chips and popcorn.

Q3: How do machines prevent puffed snack breakage?

A: Soontrue machines use gentle conveying systems and optimized sealing to minimize damage during high-speed runs.

Q4: What filling systems are best for puffed snacks?

A: Multi-head weighers ensure accurate dosing and reduce product giveaway in puffed snack packaging.

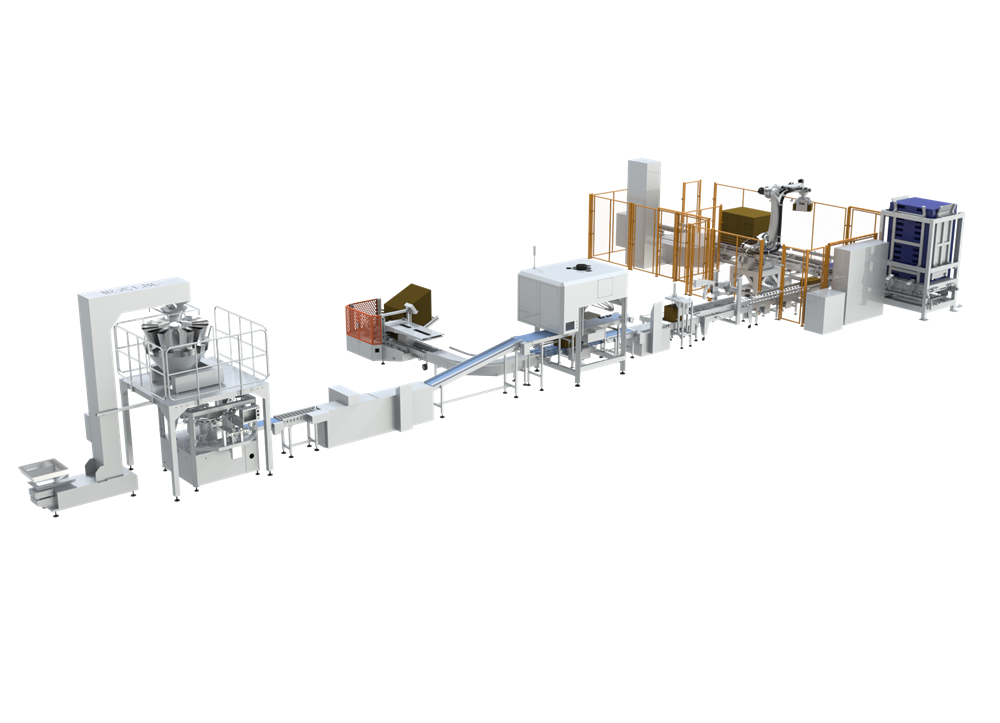

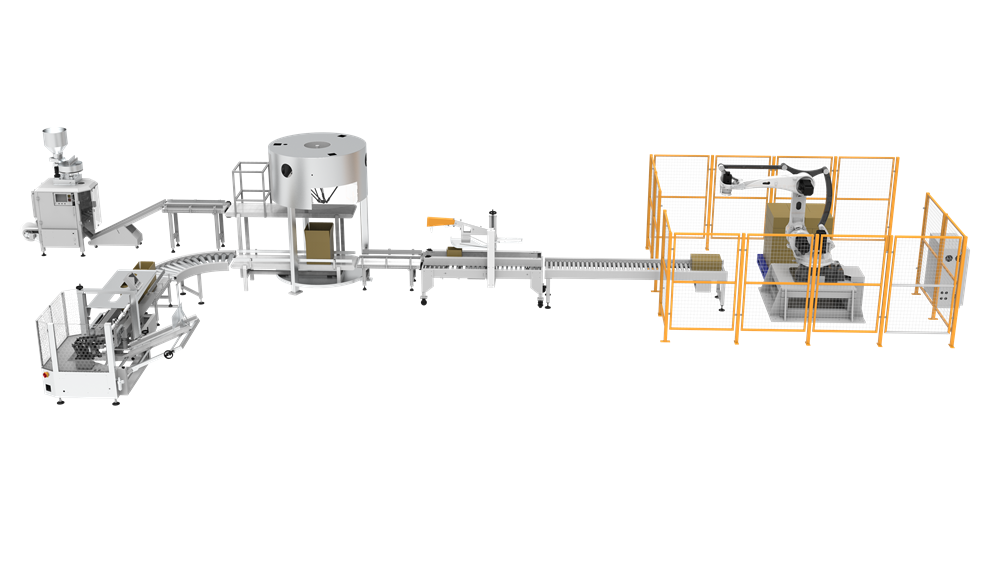

Together, these machines form a fully automated puffed food packaging line for snacks of all sizes and formats.