SZ601 Flow Packing Machine

SZ601 Flow Packing Machine Typical Applications

- Snacks & Confectionery: biscuits, cookies, candy, chocolate bars, chips.

- Bakery: bread, cakes, buns, mooncakes.

- Daily Products: tissues, wipes, sanitary goods, disposable items.

- Frozen Food: dumplings, seafood, meat cuts (regular-shaped).

- Industrial: small hardware kits, consumer goods.

The SZ601 Bottom Film Flow Packing Machine is a horizontal rotary sealing system engineered for 20–100 packs/min and film widths up to 600 mm. Unlike box motion models such as SZ601W and SZ602W, the SZ601 uses rotary sealing to achieve higher speeds while maintaining reliable pack quality.

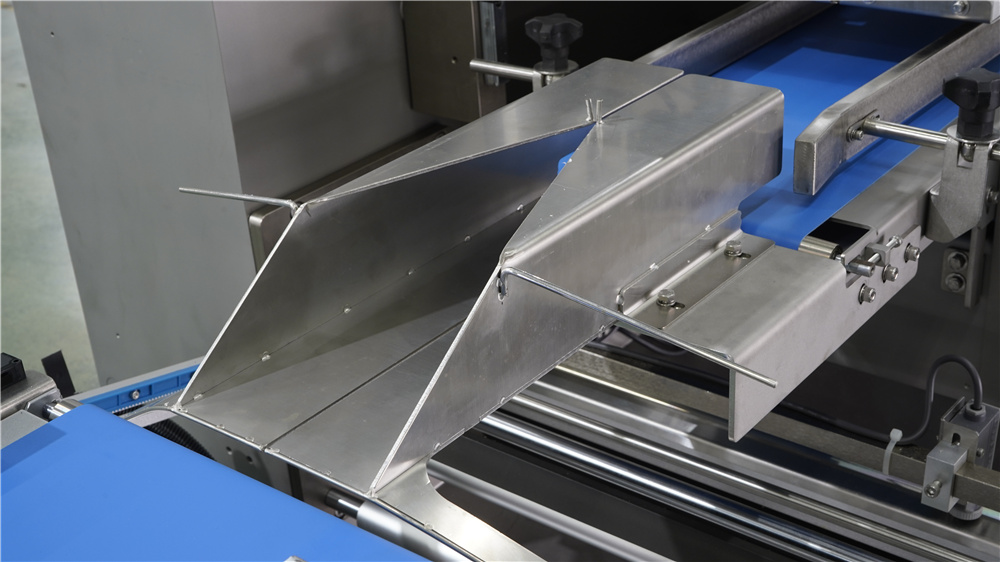

Its bottom film feeding system keeps products firmly positioned on the infeed conveyor, making it suitable for regular, lightweight, or soft products that benefit from stable handling during packaging.

Constructed with a stainless steel frame, the SZ601 ensures hygiene and durability for food and non-food industries alike. Combined with servo-driven film control, the machine delivers accurate registration, consistent sealing, and reduced waste—a cost-efficient solution for manufacturers needing speed, hygiene, and reliability.

Machine Parameters

| Specifications | SZ-601 | SZ-601 | SZ-601W | SZ-601W |

| Centerdistanoe | 150 mm | 192 mm | 120 mm | 160 mm |

| Bagging size range | L120-600 mm | L120-600 mm | L120-600 mm | L120-600 mm |

| W20-80 mm | W70-200 mm | W70-200 mm | W70-200mm | |

| Product size range | H20-80 mm | H70-100 mm | H5-80 mm | H 60-120 mm |

| Packing speed | 25-100 bags/min | 20-80 bags/min | ||

| Packing fim width | Max.600 mm | Max.600 mm | ||

| General power | 8.0 kw | 9.0 kw | ||

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz | ||

| Machine weight | 700 kg | 850 kg | ||

| Machine dimensions | 5130x1430x 1480 mm | 5350x1230x1470 mm | ||

| Packing material | CPP,OPP,PVC,OPP/CPP,PT/PE,KOP/CPP etc. | PP,PVC,PS,EVA.PRT,PVDC+PVC,OPP+CPP etc | ||

| View Machine | ||||

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

- Bottom Film Feeding: Unlike the SZ602, which uses top film feeding, the SZ601 is equipped with bottom film feeding, making it ideal for packaging delicate or easily displaced products, ensuring precise and stable packing.

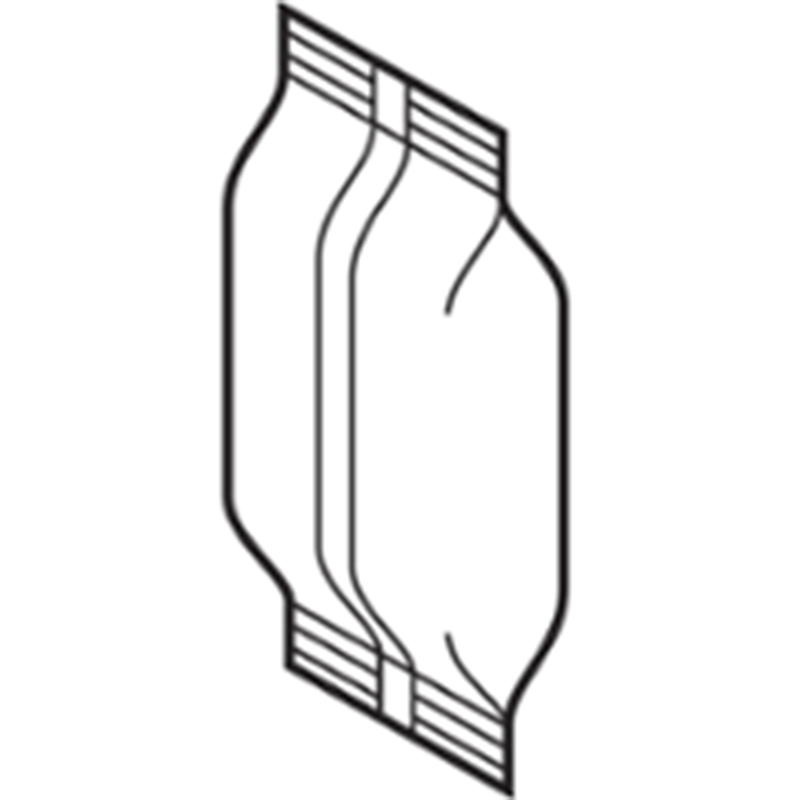

- Flow Wrap Packaging: The SZ601 excels in flow pack packaging, offering flexible and efficient packaging solutions for a wide range of products, particularly in food and non-food industries.

- High Efficiency and Precision: The machine's servo-driven system ensures high precision, consistent operation, and reliable packaging quality, maximizing productivity in high-demand environments.

- Stainless Steel Construction: Built with a full stainless steel body, the SZ601 guarantees long-lasting durability and hygiene, making it ideal for industries with strict sanitation standards.

Application

Bag Type

Competitive Advantage

Many buyers face issues with unstable feeding, poor seals, or machines that don't match their production needs. The SZ601 overcomes these challenges:

- Stability vs. Misfeeds: Top film machines can cause product shifting. The SZ601's bottom film system keeps items stable, ensuring accurate sealing and less waste.

- Speed vs. Seal Quality: Box motion models (e.g. SZ601W, SZ602W) seal stronger but run slower. The SZ601's rotary sealing reach up to 100 ppm, providing higher throughput for regular-shaped products.

- Hygiene vs. Corrosion Risks: Economic carbon steel wrappers corrode over time. The SZ601's stainless steel body ensures food safety and long service life.

- Cost vs. ROI: High-end box motion machines may exceed buyer budgets. The SZ601 balances affordability with reliable sealing, giving a faster payback period.

👉 The SZ601 is the ideal choice for snacks, bakery, and daily-use manufacturers needing speed, hygiene, and product stability.

Why Choose Soontrue as Your Flow Packing Machine Manufacturer?

Soontrue eliminates the risks buyers often face with packaging equipment. Many suppliers offer low-cost machines with weak seals, unstable performance, and poor support. With 30+ years of expertise, 600+ patents, and installations in 120+ countries, Soontrue provides proven reliability.

The SZ601 Flow Packing Machine combines bottom film feeding, rotary sealing, stainless steel design, and servo-driven precision to deliver strong ROI. Backed by CE/FDA certifications and a global service network offering installation, training, and 24/7 support, Soontrue is not just a supplier but a long-term partner in packaging automation.

FAQ About SZ601 Flow Packing Machine

Q1: What is the speed range of SZ601?

A1: The SZ601 runs at 20–100 packs/min, suitable for mid-to-high speed production.

Q2: How is SZ601 different from SZ601W and SZ602W?

A2: The SZ601 uses bottom film + rotary sealing, optimized for speed.

The SZ601W uses bottom film + box motion sealing, better for irregular/heavy products.

The SZ602W uses top film + box motion sealing, ideal for snacks/bakery needing strong seals.

Q3: Can SZ601 handle laminated or barrier films?

A3: Yes, the rotary sealing provide reliable seals for laminated snack and bakery films.

Q4: What type of products are best suited for SZ601?

A4: Regular-shaped, lightweight or medium-weight products such as biscuits, bread, cakes, candy, tissues, and frozen items.

Q5: What after-sales support is provided?

A5: Soontrue offers on-site installation, training, spare parts supply, and 24/7 service, ensuring global reliability.