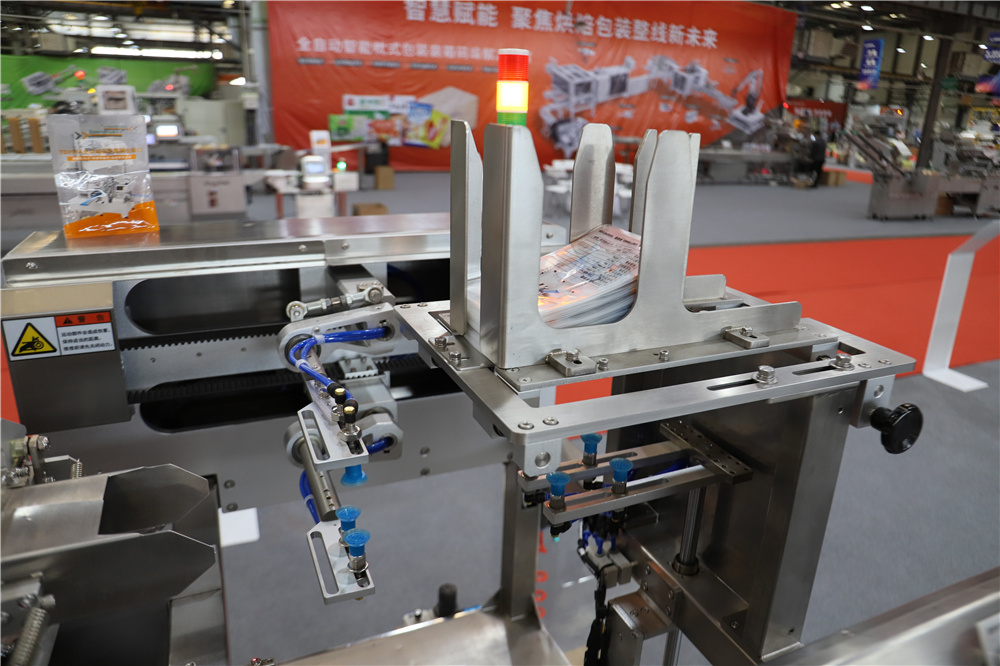

TD200L Vertical Premade Pouch Packing Machine

TD200L

Versatile Packaging Solution for Diverse Products

- Servo control

- Stainless steel machine body

- External compressed air required

The TD200L is a high-performance vertical premade pouch packaging machine designed for efficient and reliable packaging of various products. With a focus on flexibility and speed, this machine is perfect for a wide range of industries, including food, pharmaceuticals, and consumer goods. It offers exceptional packaging precision and is engineered to handle premade pouches of different shapes and sizes, providing a versatile solution for your packaging needs.

The TD200L is an excellent choice for businesses looking for a reliable, high-speed, and versatile solution for their vertical pouch packaging needs. Whether you're in the food, pharmaceutical, or consumer goods industry, this machine delivers optimal performance, flexibility, and efficiency to meet the demands of modern production lines.

Machine Parameters

| Specifications | TD200L |

| Pouch length | 150-250 mm |

| Pouch width | 50-150 mm |

| Pouch height | 40-100 mm |

| Packing speed | 10-40 pouches/min |

| General power | 8.0 Kw |

| Power supply | 220V/1Ph/50Hz |

| Machine weight | 650 kg |

| Machine dimensions | 1420x988x1500 mm |

| Packing material |

OPP/CPP, PT/PE, aluminum film, KOP/CPP aluminum laminated film |

Key Features

Vertical Premade Pouch Packaging: The TD200L is specifically designed for vertical pouch filling and sealing, allowing it to handle a variety of premade pouch styles, such as stand-up pouches, flat pouches, and more. Its vertical design offers superior space efficiency, perfect for high-speed packaging lines.

High-Speed and Precision: Equipped with advanced servo motor control, the TD200L ensures high-speed operation while maintaining precise pouch positioning. This results in consistent and reliable packaging performance, reducing waste and downtime.

Adaptable for Various Products: This machine is suitable for packaging a wide range of products, including powders, granules, and pastes. Whether you're packaging food products, chemicals, or other consumer goods, the TD200L is equipped to handle diverse product types with ease.

Flexible and Customizable: The TD200L can be easily adjusted to accommodate various pouch sizes, making it a highly flexible option for manufacturers.

User-Friendly Interface: The machine is equipped with an intuitive touch-screen interface, making it easy for operators to set parameters, monitor production, and adjust settings in real time. This user-friendly design reduces the learning curve and increases operational efficiency.

Robust and Hygienic Construction: Built with stainless steel, the TD200L ensures a durable and easy-to-clean machine body, making it ideal for industries requiring high hygiene standards, such as food and pharmaceuticals.

Application

Bag Type

Optional Configuration

Quad seal bag assembly

Flat bottom bag assembly

Doy-style bag assembly

Gusset bag assembly

Washdown construction

Hole punch (Euroslot or Round)

Product settler

Gas flush

Static elimination

Tear notch

Remote diagnostics

Integration with variety of fllers,printers,metal detectors,label applicators,and checkweighers