Automated Premade Pouch Packaging Solution

Automated Premade Pouch Packaging Solution Typical Applications

- Food Industry: Snacks, nuts, coffee, tea, rice, frozen foods, pet food

- Powders & Granules: Milk powder, protein powder, spices, fertilizers

- Liquids & Pastes: Sauces, condiments, dairy, oils, gels

- Household & Personal Care: Detergents, shampoos, lotions

- Pharmaceuticals & Healthcare: Capsules, tablets, herbal powders

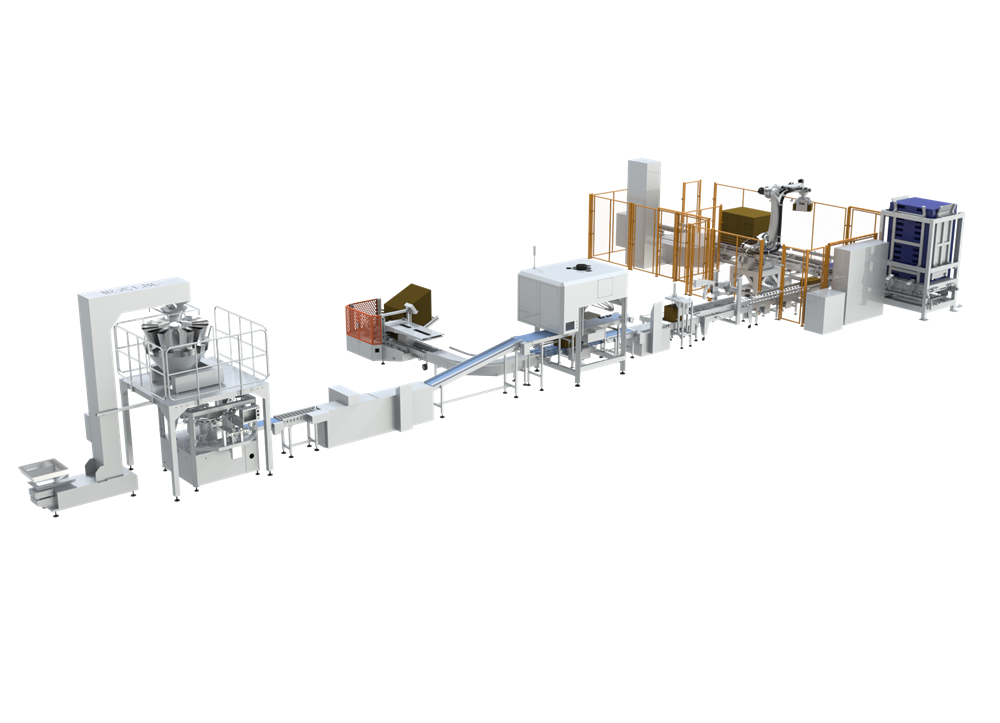

An Automated Premade Pouch Packaging Solution is a fully automated system designed to fill and seal products into pre-formed pouches such as stand-up pouches, zipper bags, flat pouches, and spouted bags. Unlike form-fill-seal machines that create bags from a film roll, this solution works with ready-made pouches provided by suppliers, offering greater flexibility in pouch design, branding, and reseal features.

Think of it as a pouch-handling specialist:

- Empty pouches are automatically picked from a magazine.

- Each pouch is opened, filled with product, and sealed securely.

- Optional modules (like zipper sealing, spout insertion, or date coding) can be added.

Why It Matters

- Premium branding: Pre-formed pouches have a more attractive look and are ideal for retail shelves.

- Flexibility: Supports multiple pouch types and sizes on one machine.

- Convenience: Perfect for resealable zippers, spouts, or high-value packaging formats.

- Efficiency: Reduces manual handling while maintaining high output and consistency.

How It Works

- Pouch Feeding – Pouches are picked from a pouch magazine and transferred to the machine.

- Pouch Opening & Detection – Pouches are opened by vacuum suction, with sensors ensuring correct positioning.

- Product Filling – Products are filled into the pouch using customized filling systems: auger fillers (powders), multi-head weighers (granules/snacks), or pumps (liquids/pastes).

- Sealing – Heat sealing or zipper sealing ensures the pouch is securely closed.

- Optional Functions – Spout sealing, gas flushing (MAP), labeling, or date coding.

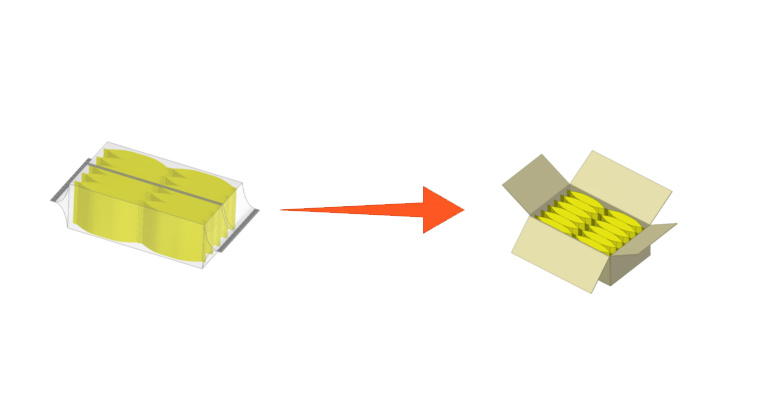

- Discharge – Finished pouches are conveyed for cartoning, case packing, or palletizing.

👉 In short, this solution allows manufacturers to achieve attractive, versatile, and reliable pouch packaging with minimal manual intervention.

Machine Parameters

Key Features

Custom-built premade pouch packing machine: Designed to handle premade pouches of various sizes and materials, the machine is tailored to your product’s specific needs, offering a flexible and reliable packaging process.

High-speed and precise filling: Capable of filling pouches quickly and accurately, the system ensures efficient packaging of products, reducing waste and maintaining high quality.

Versatile pouch styles: This solution can handle a wide range of pouch styles, including flat pouches, stand-up pouches (doypacks), zipper pouches, and more, making it ideal for food, personal care, and other industries.

Seamless integration with end-of-line automation: After primary packaging, the pouches are automatically transferred to the end-of-line systems, including case erecting, case packing, and robotic palletizing, creating a fully automated workflow from start to finish.

Hygienic stainless-steel construction: Built to meet strict hygiene standards, this system is ideal for industries such as food, pharmaceuticals, and cosmetics, ensuring compliance with industry regulations.

Application

-

Biscuit & Cookie Packaging Solutions

-

Bread & Bakery Packaging Solution

-

Chocolate Packaging Solutions

-

Noodle Packing Solutions

-

Coffee Powder Packaging Solutions

-

Nuts Packaging Solutions

-

Oil Packaging Solutions

-

Candy Packaging Solutions

-

Dried Fruits Packaging Solutions

-

Puffed Food Packaging Solutions

-

Detergent Powder Packaging Solutions

-

Other Powder Packaging Solutions

-

Seasoning Powder Packaging Solutions

-

Pet Food Packaging Solutions

-

Medical Supplies Sterile Packaging Solutions

-

Personal Care Liquid Packaging Solutions

-

Sauce Packaging Solutions

-

Beverage Packaging Solutions

-

Secondary Packaging (Random Bag Packaging Solutions)

-

Carton & Box Secondary Packaging Solutions

Bag Type

Competitive Advantage

While many suppliers focus on standard vertical form-fill-seal systems, Soontrue provides a dedicated premade pouch packaging solution that offers unmatched flexibility. Our system handles a wide variety of pouch formats and resealable features, ensuring that your products stand out on retail shelves. Compared with traditional packaging solutions, Soontrue delivers higher precision, faster changeovers, and enhanced branding value. With our engineering expertise and global service support, we provide a complete, premium solution for businesses targeting high-end consumer markets.

Why Choose Soontrue?

With more than 30 years in the packaging industry, Soontrue has become a trusted partner for global manufacturers. Our premade pouch packaging solutions combine advanced automation with flexibility, making them ideal for both mass production and premium product lines. We design systems tailored to customer needs, supported by a global service network that ensures smooth implementation and long-term reliability. Choosing Soontrue means choosing a partner committed to innovation, product quality, and your brand success.

FAQ About Automated Premade Pouch Packaging Solution

Q1: What if a pouch fails to open or is defective?

The machine includes advanced pouch detection sensors. If a pouch does not open correctly or is missing, it will be automatically rejected before filling, preventing spills, waste, and contamination.

Q2: Will using premade pouches increase packaging costs?

While premade pouches are typically more expensive than roll film, they deliver superior branding, reseal features, and consumer convenience. This higher shelf appeal often translates into stronger sales and better margins, offsetting the initial cost.

Q3: Can the system handle fragile or messy products like powders and sauces?

Yes. Soontrue integrates different filling systems—auger fillers for powders (preventing dust leakage), multi-head weighers for fragile snacks, and pumps for sauces or liquids. Each filler is designed for accuracy and product integrity, ensuring consistent quality across product types.

Q4: What about production speed—are premade pouch machines slower than form-fill-seal machines?

Not with Soontrue. Our automated pouch line can run at high speeds while maintaining accuracy, and pouch feeding is synchronized with filling and sealing. For premium packaging formats (zipper/spouted pouches), this solution balances speed with brand presentation value.

Q5: How reliable is the sealing quality?

We use temperature-controlled sealing jaws and pressure monitoring to guarantee consistent seals. Options like zipper re-closure sealing and gas flushing (MAP) ensure extended shelf life and strong market acceptance.

Q6: What if I need to scale up in the future?

The system is modular and upgradeable. You can start with a basic pouch filler and later integrate nitrogen flushing, spout sealing, labeling, or even end-of-line automation like case packing and palletizing.

Q7: How strong is the after-sales support?

Soontrue provides a global service network, with overseas engineers, local spare parts depots, and 24/7 online support. We also offer operator training and remote diagnostics to ensure smooth long-term operation.