ZL180YT Integrated Vertical Packaging Machine

ZL180YT Integrated Vertical Packaging Machine for Typical Applications

- Granules: rice, beans, nuts, sugar, salt

- Snacks & Baked Goods: chips, candies, bread, biscuits

- Frozen items: dumplings, frozen vegetables, small seafood packs

- Household & Daily Items: small disposable products, personal care samples

- Hardware & Industrial Parts: screws, nails, fasteners, small metal accessories

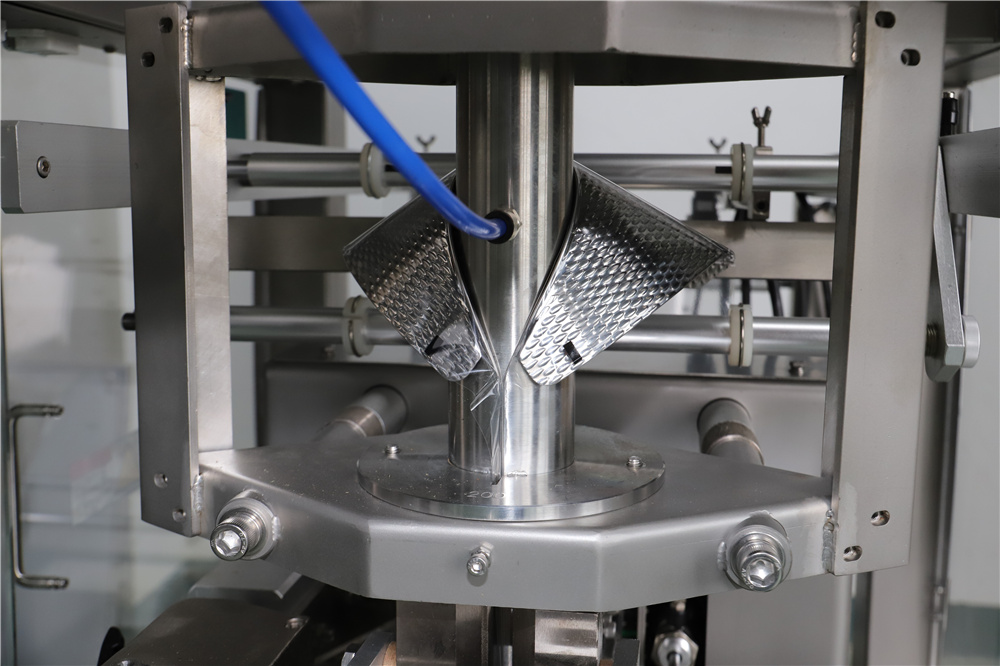

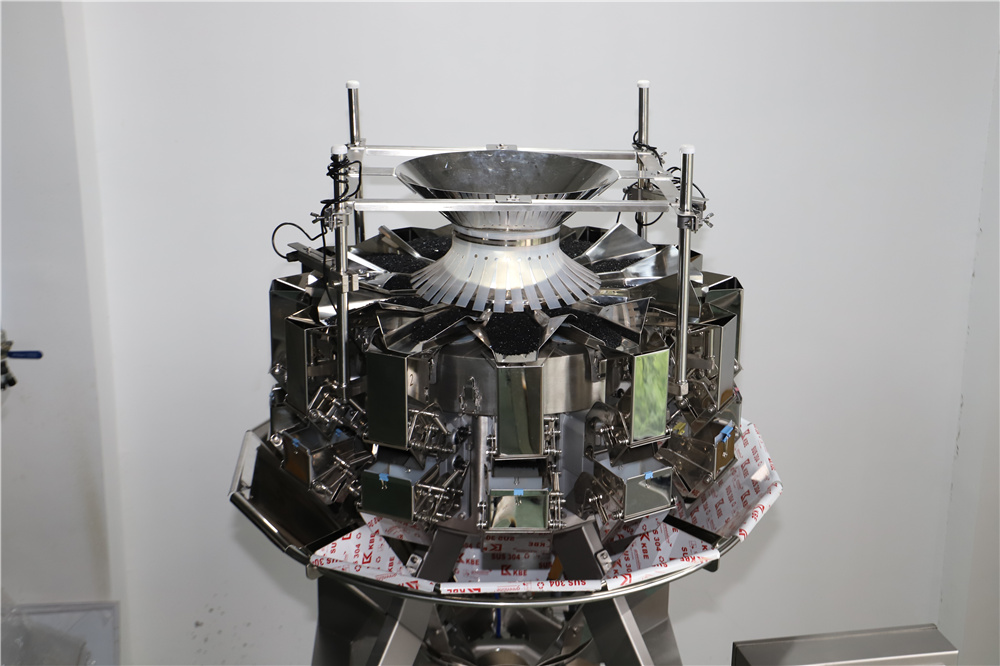

The ZL180YT Integrated Vertical Packaging Machine is an innovative, space-efficient solution that combines a 12 or 14-head multi-head weigher with a vertical packaging system. Unlike conventional setups that require separate machines for weighing and bagging, this all-in-one design significantly reduces footprint while maintaining the same high-level performance.

Engineered for small to medium bag sizes, the ZL180YT delivers precise, fast, and consistent weighing for a wide variety of products, from snacks, rice, nuts, and frozen foods to small hardware items such as screws and fasteners. Its integrated system not only saves valuable production space but also minimizes setup complexity and ongoing maintenance.

By offering efficient space utilization, high accuracy, and flexible packaging formats, the ZL180YT is an excellent choice for manufacturers seeking to maximize productivity while reducing operational costs. Whether for food industries or non-food sectors, this machine ensures reliable performance in a compact and versatile package.

Machine Parameters

| Specifications | ZL180YT | ZL180YT |

| Bagging size range | L50-190 mm | L50-190 mm |

| W50-150 mm | W50-150 mm | |

| Packing fim width | 100-320 mm | 100-320 mm |

| Multi-head weigher | 12 heads 0.8L | 14 heads 0.5L |

| Packing speed | 20-80 bags/min | 20-100 bags/min |

| General power | 5.4 Kw | 5.5 Kw |

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz |

| Machine weight | 510kg | 510kg |

| Machine dimensions | 2500x1250x1670 mm | 2520x1210x1650 mm |

| End Sealing | Open-close motion | |

| Packing material |

PP,CPP,PVC,PS,EVA,PET,PVDC+PVC,OPP/CPP,etd. |

|

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

- Compact All-in-One Design:Integrates multi-head weigher and vertical packaging system into one unit, reducing footprint.

- Precision Weighing:12 or 14-head multi-head weigher ensures fast and accurate dosing.

- Versatility Across Industries:Equally effective for food (snacks, nuts, frozen food) and non-food (hardware, disposables).

- Small Bag Efficiency:Optimized for small to medium pouch sizes with consistent sealing quality.

- Quick Changeovers:Recipe storage system minimizes downtime when switching products.

- User-Friendly Operation:Touchscreen HMI with multi-language options for global users.

Application

-

Biscuit & Cookie Packaging Solutions

-

Candy Packaging Solutions

-

Chocolate Packaging Solutions

-

Dried Fruits Packaging Solutions

-

Frozen Food Packaging Solutions

-

Nuts Packaging Solutions

-

Puffed Food Packaging Solutions

-

Pet Food Packaging Solutions

-

Rice & Cereal Packaging Solutions

-

Sugar & Salt Packaging Solutions

-

Medical Supplies Sterile Packaging Solutions

-

Secondary Packaging (Random Bag Packaging Solutions)

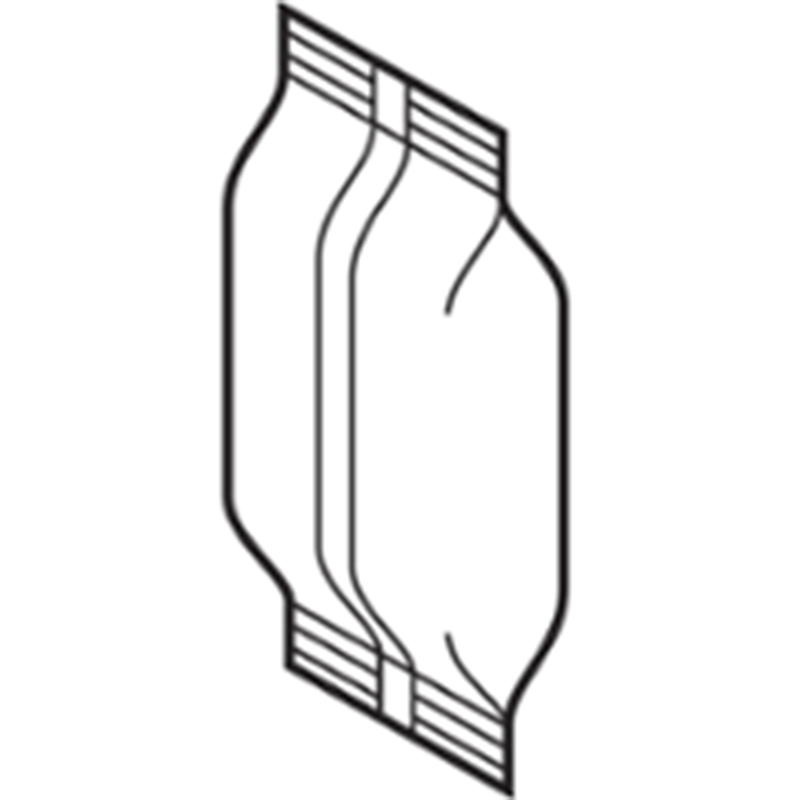

Bag Type

Competitive Advantage

Compared to conventional vertical packaging setups that require a separate multi-head weigher and bagging machine, the ZL180YT integrates both into one compact unit. This saves up to 30% factory floor space, reduces equipment investment, and minimizes maintenance complexity. While competitor machines may struggle to maintain accuracy at high speeds or require more frequent adjustments, the ZL180YT ensures consistent weighing precision, stable sealing, and faster ROI for small to medium bag packaging.

Why Choose Soontrue?

Choosing Soontrue means partnering with a company that has over 30 years of expertise in packaging automation. The ZL180YT reflects our commitment to efficient, space-saving, and versatile packaging solutions tailored to both food and non-food industries. Backed by a global service network and continuous R&D, Soontrue ensures your investment delivers long-term value and adaptability as your business grows.

FAQ - ZL180YT Integrated Vertical Packaging Machine

Q1: What bag sizes can the ZL180YT handle?

It is optimized for small to medium bag sizes, making it ideal for snack packs, rice, nuts, frozen food, and hardware items.

Q2: How much space does this integrated design save?

By combining the multi-head weigher and packaging system, the ZL180YT can reduce footprint by up to 30% compared with separate machines.

Q3: Can it handle both food and non-food products?

Yes. It is equally suited for granules, snacks, frozen food, and small hardware items, ensuring flexibility for different industries.

Q4: How does it compare with traditional VFFS machines?

Unlike standard machines requiring separate weighing systems, the ZL180YT delivers precision weighing and packaging in one, reducing equipment costs and setup time.

Q5: Is it suitable for SMEs as well as large manufacturers?

Absolutely. Its compact design is perfect for SMEs with limited floor space, while its robust capacity supports large-scale production lines.