GDS210-08 Premade Pouch Packaging Machine

GDS210-08

Versatile Packaging Solution for Diverse Products

- Servo control

- Stainless steel machine body

- External compressed air required

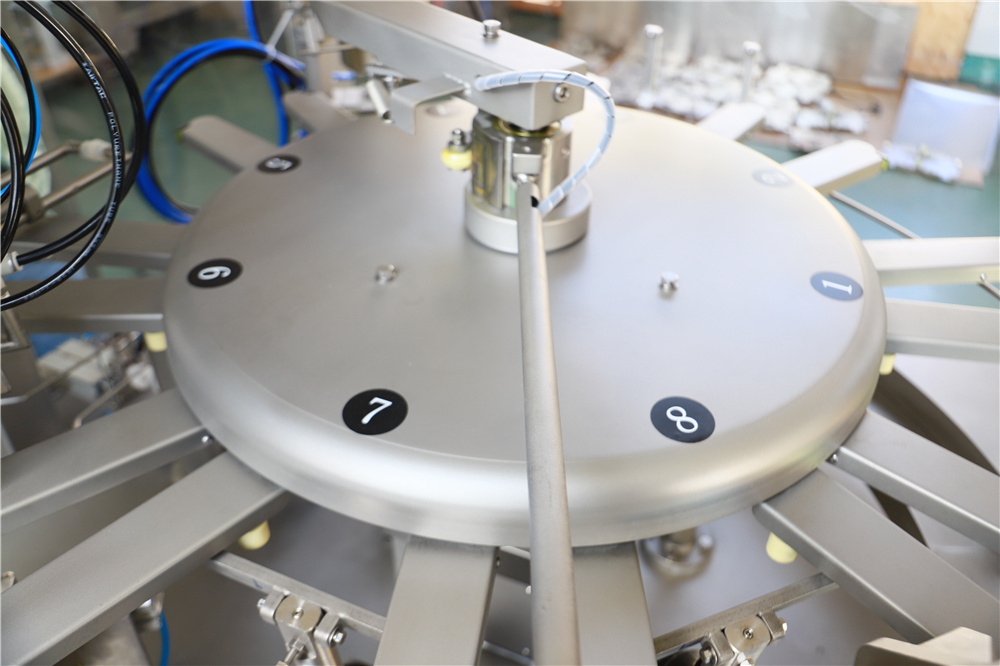

The GDS210-08 is a highly efficient and versatile vertical premade pouch packaging machine designed with 8 working stations to meet the demanding needs of modern packaging operations. This machine is engineered to handle high-speed production while maintaining precision, making it an ideal solution for various industries that require reliable and customizable packaging systems.

The GDS210-08 is perfect for businesses requiring a highly versatile premade pouch filling machine that offers high-speed performance and reliable precision. With its rotary design, customizable weighing options, and compatibility with various pouch types, this machine delivers superior automatic bagging solutions. Its durable construction and user-friendly interface make it a powerful addition to any production line, enhancing productivity while reducing downtime.

Machine Parameters

| Specifications | GDS180-06 | GDS210-08 | GDS210-10 | GDS260-08 | GDS300-08 |

| Working stations | 6 | 8 | 10 | 8 | 8 |

| Bagging size range | L ≦360 mm | L 120-380 mm | L 120-380 mm | L ≦400 mm | L 400 mm |

| W 70-180 mm | W80-210 mm | W80-210 mm | W130-260 mm | W160-300 mm | |

| Packing speed | ≦60 pouches/min | ≦70 pouches/min | ≦100 pouches/min | ≦72 pouches/min | ≦72 pouches/min |

| General power | 3.4 Kw | 8.0 Kw | 8.0 Kw | 8.0 Kw | 8.0 Kw |

| Power supply | 380V/3Ph/50Hz | 380V/3Ph/50Hz | 380V/3Ph/50Hz | 380V/3Ph/50Hz | 380V/3Ph/50Hz |

| Machine weight | 400 kg | 500kg | 600 kg | 580 kg | 650 kg |

| Machine dimensions | 1500x900x1460 mm | 1700x1140x1470 mm | 1900×1340x1520 mm | 1850×1250x1520 mm | 2100×1500x1520 mm |

| Premade bag | Flat pouch,stand-up pouch, zipper pouch, top seal pouch, doypack pouch,etc. | ||||

| Packing material |

Single layer PE, PE laminated film, paper film and other laminated film |

||||

| View Machine | View Machine | View Machine | View Machine | ||

Key Features

Eight Working Stations for Increased Productivity: With its advanced 8-station rotary design, the GDS210-08 enhances productivity by allowing multiple stages of the packaging process to occur simultaneously. This structure maximizes output, making it perfect for high-volume applications in industries such as food, cosmetics, and pharmaceuticals.

Versatile Packaging Options: The GDS210-08 is compatible with a wide range of pouch types, from flat pouches to stand-up pouches, offering flexibility to businesses with diverse packaging needs. Whether you're looking to package powders, granules, liquids, or solid items, this machine is tailored to adapt to various product types with precision.

Customizable Weighing and Filling Tools: To ensure precise filling, the GDS210-08 can be equipped with optional tools like volumetric cups, augers, multi-head weighers, or liquid pumps, providing accurate and consistent filling for a wide array of products. This addresses concerns about product waste and packaging consistency, crucial for maintaining quality and efficiency.

Rotary Premade Pouch Technology: The GDS210-08’s rotary premade pouch system ensures smooth and continuous operation. This efficient system allows for the quick and seamless handling of pouches, making it an ideal automatic bagging machine for businesses looking to streamline their packaging lines.

Application

Bag Type

Optional Configuration

Quad seal bag assembly

Flat bottom bag assembly

Doy-style bag assembly

Gusset bag assembly

Washdown construction

Hole punch (Euroslot or Round)

Product settler

Gas flush

Static elimination

Tear notch

Remote diagnostics

Integration with variety of fllers,printers,metal detectors,label applicators,and checkweighers