Automatic Packaging Line With Tray

Automatic Packaging Line With Tray Typical Applications

- Bakery products: mooncakes, pastries, bread rolls, sliced cakes.

- Confectionery & snacks: chocolate assortments, delicate candies, multi-piece snack sets.

- Frozen & ready meals: dumplings, dim sum, prepared food portions.

- Special retail packs: promotional combo trays, gift assortments.

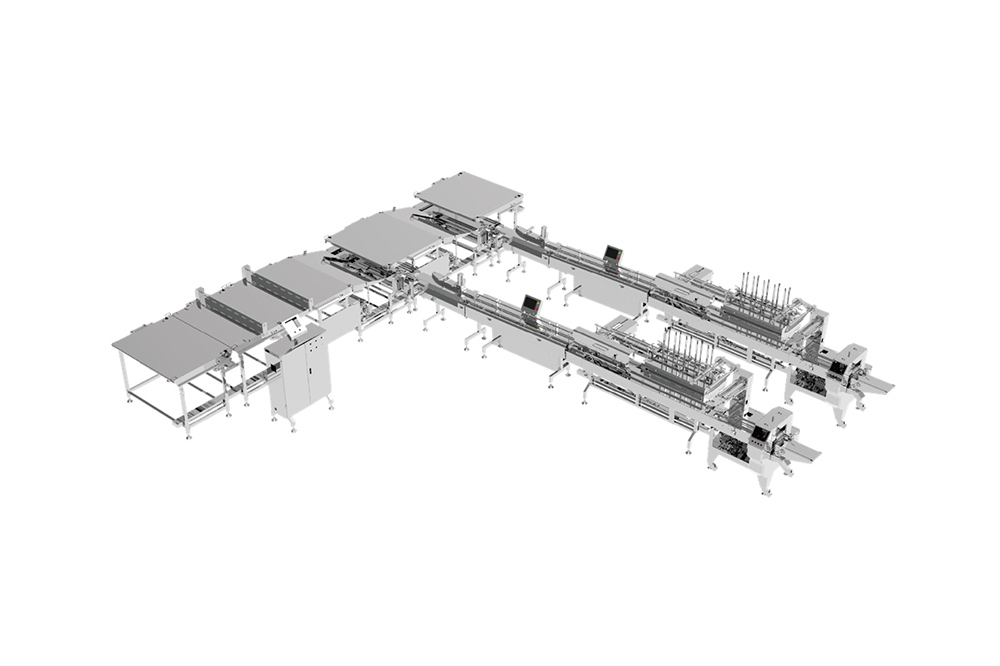

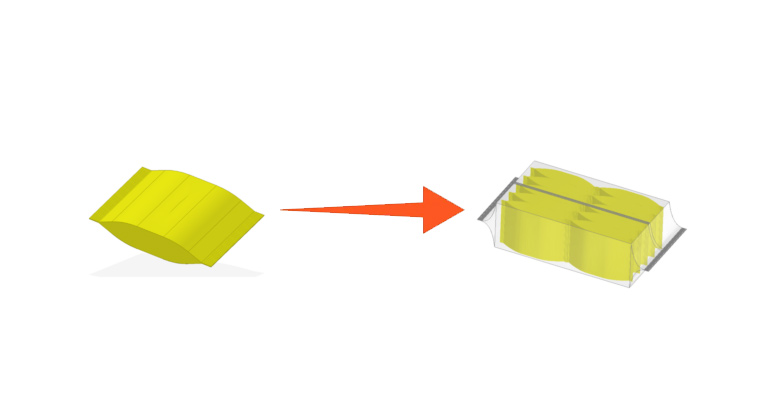

An Automatic Packaging Line With Tray is a specialized solution that combines tray loading with pillow bag (back-seal/fin-seal) wrapping to create retail-ready packs that are both protective and visually appealing. It is designed for products that are too fragile or premium to be packed directly into pillow bags, but still require the hygiene and shelf-life benefits of sealed film.

Why use tray-in-bag packaging?

- Tray stability – The tray holds delicate or multi-piece products in place, preventing crushing and deformation during wrapping and transport.

- Film hygiene & preservation – The pillow bag provides a sealed environment that protects against moisture, dust, and contamination.

- Retail presentation – The combination delivers a professional, attractive look that enhances shelf impact.

Step-by-step process explained:

- Product preparation – Biscuits, cakes, or confectionery items exit the cooling line and are aligned for feeding.

- Tray dispensing – Pre-formed trays (plastic, paper, or foil) are automatically placed onto the conveyor.

- Tray loading – Products are counted and loaded into trays via servo pushers or mechanical loaders (robotic pick-and-place optional for complex orientation).

- Film wrapping (pillow bag) – The tray with products enters the flow wrapper, where film is formed around it, creating a back seal and two end seals.

- Optional gas flushing – MAP sealing (e.g., nitrogen) can be added to extend freshness.

- Final discharge – The finished tray-in-bag pack moves downstream for cartoning, case packing, or palletizing.

👉 This dual-layer protection—tray + sealed bag—is especially valuable for bakery, confectionery, and ready-meal manufacturers who need both stability and hygienic packaging.

Machine Parameters

Key Features

- Tray + pillow bag integration – Combines tray stability with back-seal film hygiene.

- Default mechanical loaders, robot optional – Standard tray loading by servo pushers; robotic modules available for flexible placement.

- Customizable speed & layout – Scales by tray format, bag length, and wrapper configuration.

- Gentle handling – Protects fragile bakery items and delicate chocolates.

- Hygienic & food-grade – Stainless steel construction, easy cleaning, CE/ISO/FDA compliance.

- Wide tray & film compatibility – PET/PP trays, paper trays, aluminum trays; OPP/CPP, PET/PE, and metallized films.

- Box-motion sealing option – Longer dwell time for thick films or MAP packs.

- Integration-ready – Links with case packers, cartoners, palletizers.

Application

-

Chocolate Packaging Solutions

-

Biscuit & Cookie Packaging Solutions

-

Bread & Bakery Packaging Solution

-

Organized Bag Secondary Packaging Solutions

-

Dried Fruits Packaging Solutions

-

Candy Packaging Solutions

-

Frozen Food Packaging Solutions

-

Meat Poultry & Seafood Packaging Solutions

-

Puffed Food Packaging Solutions

-

Vegetable & Fruit Packaging Solutions

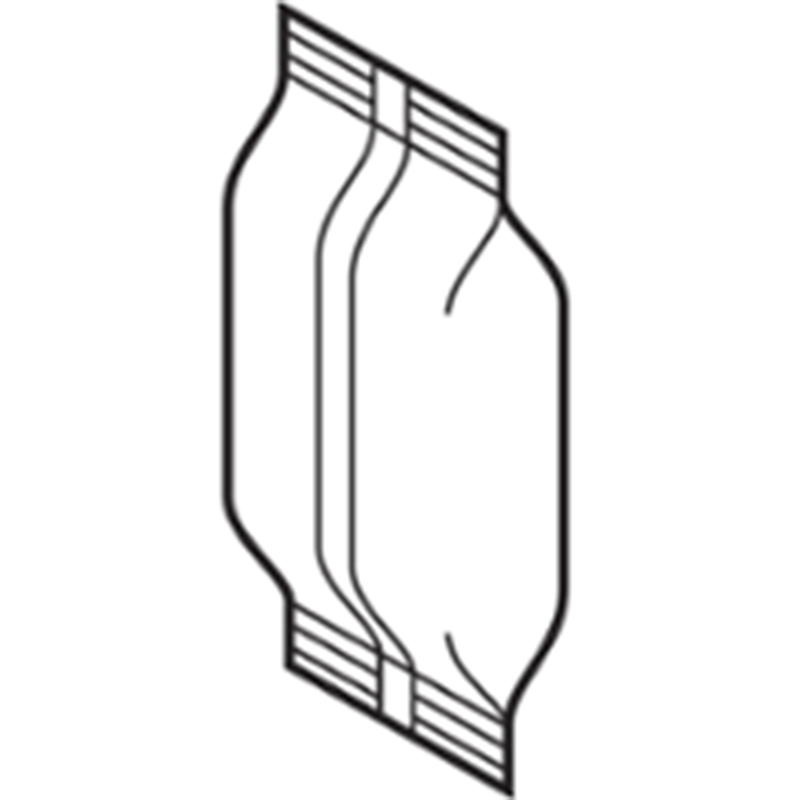

Bag Type

Competitive Advantage

Compared to separate tray loaders or standalone flow wrappers, Soontrue’s integrated tray-in-bag line delivers:

Efficiency – Continuous tray loading + wrapping eliminates manual transfer.

Reduced labor cost – Full automation replaces repetitive manual tray loading and bagging.

Better product integrity – Tray stabilizes items, pillow bag seals them airtight → fewer breakages.

Retail-ready appearance – Attractive pack presentation with tray visibility inside the bag.

Flexibility – Handles multiple tray sizes, materials, and bag lengths in one line.

Proven ROI – Automation pays back quickly in high-volume bakery & confectionery production.

Why Choose Soontrue?

When investing in tray-in-bag packaging, manufacturers face common challenges:

- Fragile products breaking during transport

- Rising labor costs for manual tray loading

- Inconsistent pack quality across shifts

- Need for scalability as order volumes grow

Soontrue helps you solve these challenges with a scalable, future-proof packaging line:

- Protects product integrity – trays and pillow bags combine to safeguard even the most delicate items.

- Balances cost and flexibility – default servo loaders minimize cost, while optional robotics handle complex SKUs.

- Designed around your throughput – capacity is configured based on your product count per tray and target bags per minute, not a one-size-fits-all design.

- Supports your growth – modular stations and wrapper options mean you can start small and expand as demand increases.

- Backed by global expertise – with 30+ years of experience and installations in 120+ countries, we know how to deliver reliable, high-speed packaging solutions.

👉 Choosing Soontrue means choosing a partner who grows with you, ensuring your tray-in-bag line stays competitive, efficient, and profitable.

FAQ About Automatic Packaging Line With Tray

Q1: What types of products are best for tray-in-bag?

A1: Fragile, premium, or multi-piece products such as cakes, mooncakes, chocolates, or prepared meals.

Q2: What trays are supported?

A2: PET, PP, paper, and aluminum trays.

Q3: What films are supported?

A3: OPP/CPP, PET/PE, metallized, and barrier laminates.

Q4: How fast can the line run?

A4: Typically 20–350 bags/min/machine, depending on tray layout and wrapper configuration.

Q5: Is robotic tray loading standard?

A5: No, standard is mechanical/servo loaders. Robots are optional for orientation-critical or fragile items.

Q6: Can MAP (gas flushing) be included?

A6: Yes, optional nitrogen flushing and box-motion sealing extend product shelf life.