ZL180P Vertical Packaging Machine

ZL180P

Versatile Packaging Solution for Diverse Products

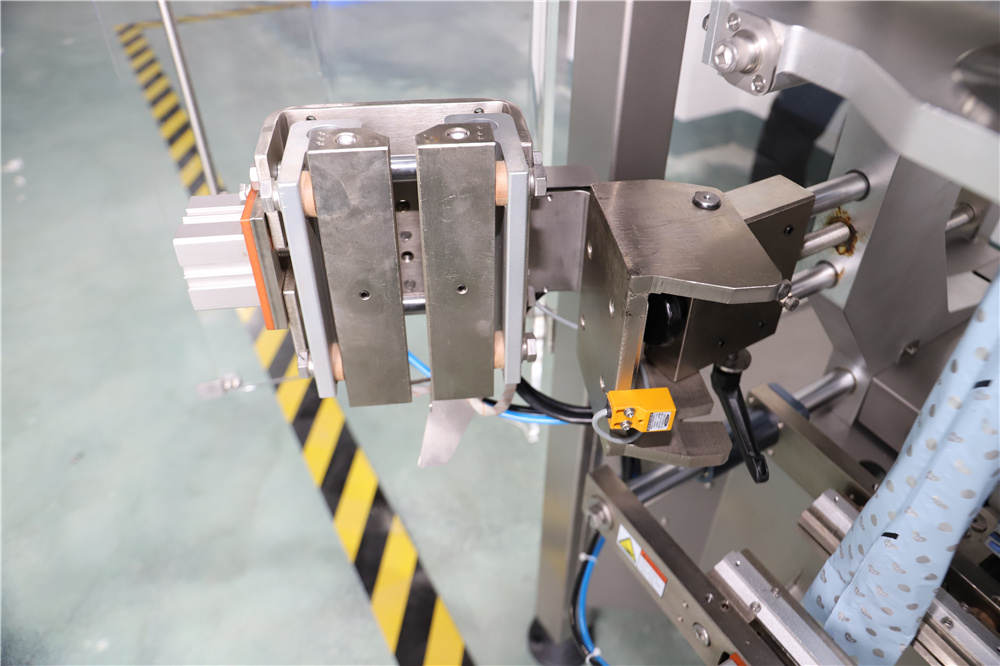

- Servo control

- Stainless steel machine body

- External compressed air required

The ZL-180P is a high-performance vertical packaging machine, designed to meet the diverse needs of modern production lines. Equipped with an advanced servo control system and durable stainless steel body, the ZL-180P ensures precise, high-speed, and reliable packaging for a variety of industries, including food and snacks. Its flexibility makes it an excellent choice for manufacturers looking for a versatile VFFS (Vertical Form Fill Seal) packaging machine solution.

This machine can be tailored to fit your specific packaging needs, whether you're working with powders, granules, liquids, or solids. The ZL-180P supports various weighing tools such as auger, volumetric cups, multi-head weighers, and liquid pumps, offering enhanced flexibility for packaging different product types.

Choosing the ZL-180P means investing in a machine that combines speed, precision, and customizability. Whether you're in need of a high-performance snack packaging machine or a vertical bagging machine, this model offers the flexibility to meet your unique product requirements. Our experienced team of R&D engineers can further customize the ZL-180P to perfectly match your product characteristics, ensuring optimal performance.

As a top vertical form fill seal machine manufacturer, Soontrue provides world-class technology and support, helping you streamline your packaging processes while maintaining high standards of product quality and consistency.

Machine Parameters

| Specifications | ZL-180P | ZL-180PH(high speed) | ZL-200P | ZL-200PH(high speed) | ZL-300P |

| Bagging size range | L50-190 mm | L50-190 mm | L 50-300 mm | L50-300 mm | L80-400 mm |

| W50-150 mm | W50-150 mm | W90-200 mm | W90-200 mm | W200-295 mm | |

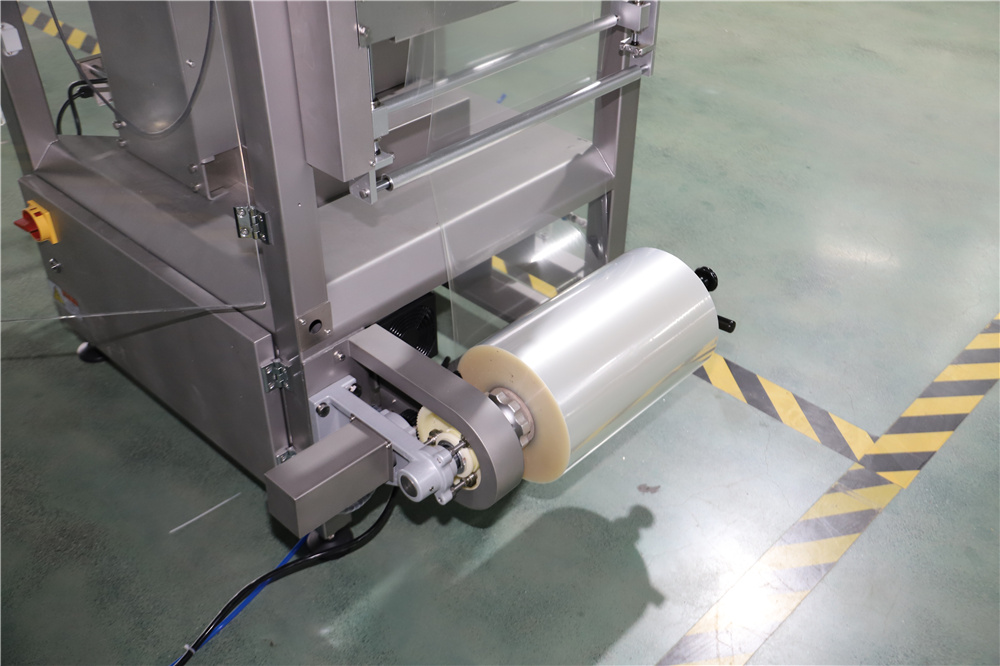

| Packing fim width | 100-320 mm | 100-320 mm | 200-420 mm | 200-420 mm | 420-620 mm |

| Packing speed | 20-100 bags/min | 20-100 bags/min | 20-90 bags/min | 20-120 bags/min | 15-60 bags/min |

| General power | 3.9 Kw | 4.65 Kw | 3.9 Kw | 4.9 Kw | 4.65 Kw |

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz |

| Machine weight | 220kg | 250kg | 240 kg | 280 kg | 600 kg |

| Machine dimensions | 1112x1170x1460 mm | 1200x1170x1460 mm | 1300×1170x1582 mm | 1427×1170x1562 mm | 1620×1380x1680 mm |

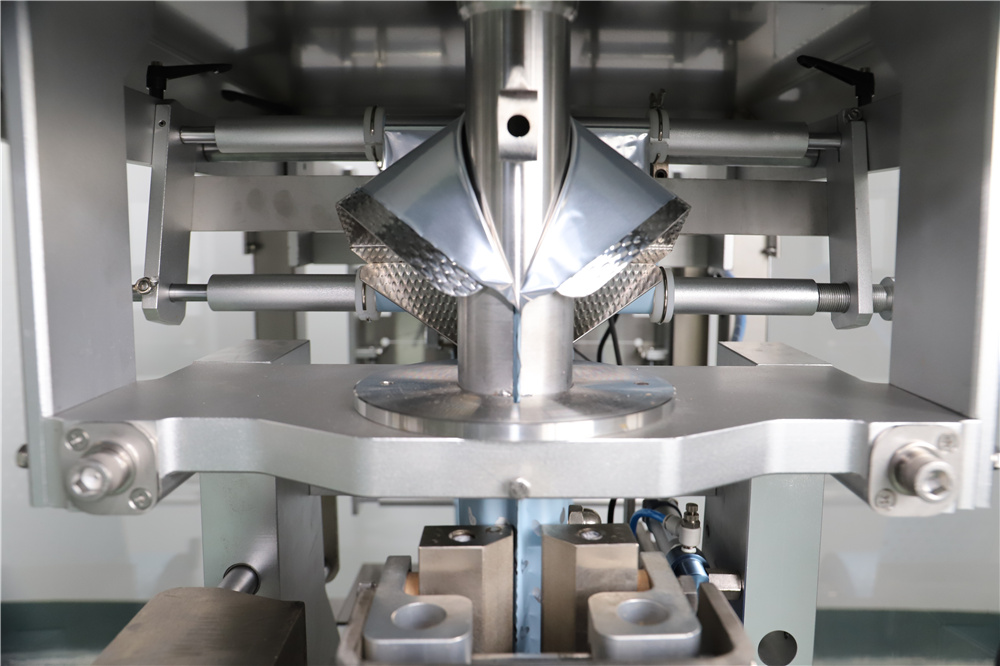

| End Sealing | Open-close motion | Continuous motion | Open-close motion | Continuous motion | Open-close motion |

| Packing material |

PP,CPP,PVC,PS,EVA,PET,PVDC+PVC,OPP/CPP,etd. |

||||

| View Machine | View Machine | View Machine | View Machine | ||

Key Features

Advanced Servo Control: Provides precise and stable packaging operations, ensuring consistent results even during high-speed production.

Durable Stainless Steel Construction: Guarantees long-lasting durability and maintains hygiene, ideal for industries with strict sanitation needs.

High-Speed Operation: Capable of packing at speeds ranging from 20 to 100 bags per minute, making it a great solution for manufacturers needing high throughput.

Flexible Bagging Sizes: Supports a wide range of bag sizes (50-190 mm length, 50-150 mm width), providing versatility for packaging various products.

Optional Weighing Tools: Compatible with auger, volumetric cups, multi-head weighers, and liquid pumps, allowing for packaging different types of products with precision.

Pillow Pouch Specialization: Expertly handles pillow pouch packaging, making it an excellent option for products like snacks and dry goods.

Application

Bag Type

Optional Configuration

Quad seal bag assembly

Flat bottom bag assembly

Doy-style bag assembly

Gusset bag assembly

Washdown construction

Hole punch (Euroslot or Round)

Product settler

Gas flush

Static elimination

Tear notch

Remote diagnostics

Integration with variety of fllers,printers,metal detectors,label applicators,and checkweighers