Automatic Packaging Line For Sandwic Biscuit

Versatile Packaging Solution for Diverse Products

- Filling injection system

- Gentle handling of multi-layer products

- Versatile packaging formats

Soontrue automatic packaging line for sandwich biscuits with filling injection goes beyond just packaging — it also integrates a high-precision filling system that injects creamy or flavored fillings between the biscuit layers, transforming them into delicious sandwich biscuits. This all-in-one solution not only ensures efficient packaging but also manages the entire process of producing and packaging sandwich biscuits, from filling to final packaging.

How It Works:

The process begins with biscuits being placed in precise alignment, after which the filling is injected between them, creating perfectly filled sandwich biscuits. The system then seamlessly moves the filled products to the packaging phase, where they can be packed as single pieces or multi-piece family packs. The flexibility of the line allows for a wide range of packaging configurations, from individually wrapped biscuits to stacked or layered formats in family-sized packs. Once arranged, the system proceeds to seal or box the products, ensuring they're ready for shipment.

Why Choose Our System:

Our company is a leading provider of advanced food packaging solutions, and this automatic packaging line offers a comprehensive solution for sandwich biscuits production and packaging, all in one seamless system:

- Complete production line: From injecting the filling to packing the final product, the system automates the entire process, increasing efficiency and consistency.

- Customization: Whether you’re producing small packs for individual consumers or large family packs, this line is customizable to meet various product sizes and configurations.

- Hygiene and safety: Designed with a focus on hygiene, the system ensures compliance with industry standards while reducing manual handling, improving both safety and product quality.

- Increased production speed: With its integrated injection and packaging capabilities, the system significantly speeds up production while maintaining product integrity and consistency.

This solution is perfect for manufacturers looking to automate both the production and packaging of sandwich biscuits, ensuring a fast, efficient, and hygienic process. With our Automatic Packaging Line for Sandwich Biscuits with Filling Injection, you can improve your production output, reduce costs, and deliver consistently high-quality sandwich biscuits to your customers.

Machine Parameters

Key Features

Filling injection system: Capable of injecting a wide variety of fillings, such as cream, chocolate, fruit flavors, or other customizable options, between biscuit layers to create sandwich biscuits.

Precise biscuit alignment and filling: Ensures even distribution of the filling, avoiding overfill or underfill, and aligning the biscuit layers perfectly for consistent product quality.

Gentle handling of multi-layer products: Maintains the integrity of both the biscuits and the filling during the entire process, preventing damage or distortion.

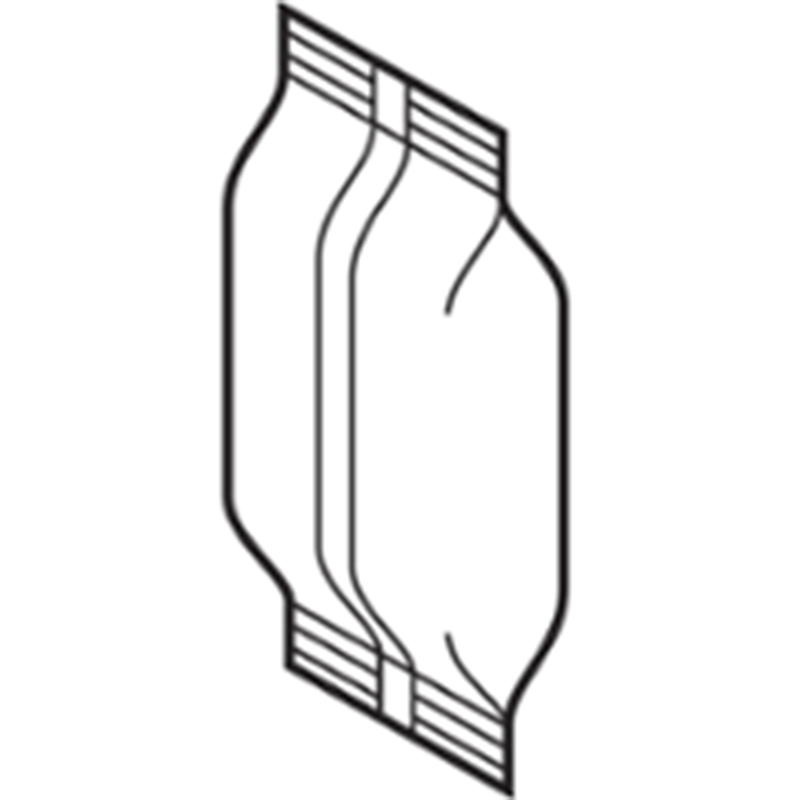

Versatile packaging formats: Can handle both single-piece and multi-piece (family pack) configurations, with the ability to stack or layer the biscuits based on customer requirements.

Hygienic and easy to clean: The system is built with food-grade materials and designed for easy disassembly and cleaning, ensuring top-notch hygiene standards.

High-speed production: Ensures fast and efficient injection, stacking, and packaging, ideal for large production runs without sacrificing quality.

Application

Bag Type

Optional Configuration