Automatic Packaging Line With Deoxidizer

Versatile Packaging Solution for Diverse Products

- Customizable for diverse product lines

- Precision in deoxidizer integration

- Fully automated workflow

- Prolongs product freshness

As a leading company in the food packaging industry, soontrue automatic packaging line with deoxidizer offers an innovative solution designed to extend product freshness and optimize shelf life. We are recognized as a domestic leader, providing cutting-edge packaging technology tailored to meet the diverse needs of food manufacturers. Our systems ensure that deoxidizer sachets are accurately placed in every package, making them indispensable for products that require low oxygen environments, such as baked goods, snacks, and vacuum-sealed products.

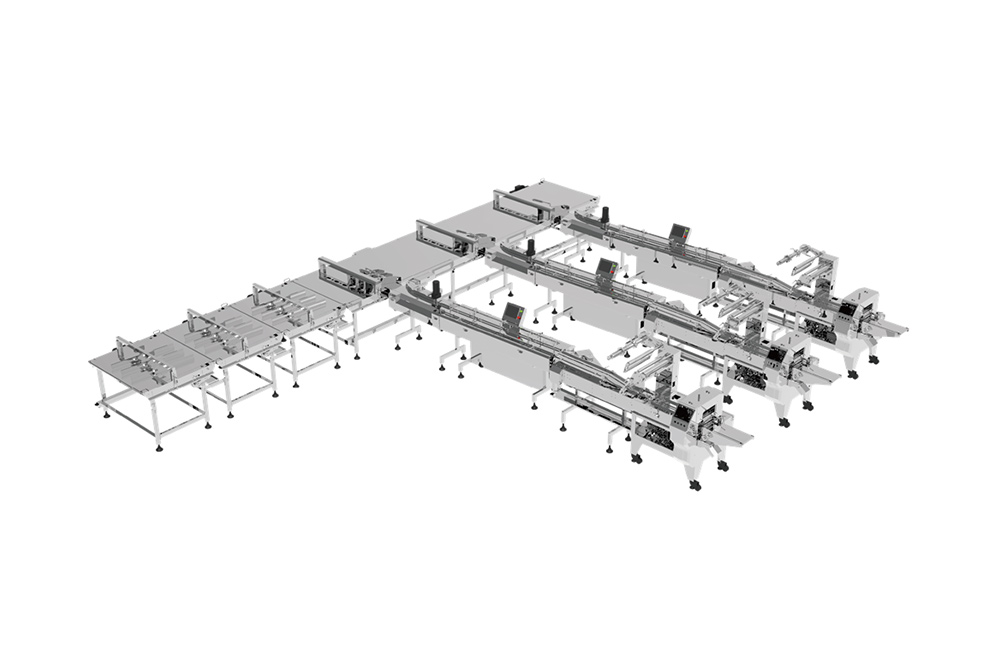

How the Automatic Packaging Line with Deoxidizer Works:

The automatic packaging line operates by first sorting and aligning the products for packaging. Once the products are in place, a deoxidizer sachet is precisely dispensed into each package. After the deoxidizer is inserted, the packaging machine completes the sealing process, ensuring that minimal oxygen remains in the package. This line is highly efficient for food items such as baked goods, snacks, and meat products that are prone to oxidation.

This type of automatic packaging line is ideal for industries with high demands for food preservation and quality control, helping brands ensure that their products maintain optimal freshness and safety.

Machine Parameters

Key Features

Industry-leading technology: Our solutions are backed by years of experience and technical expertise, positioning us at the forefront of food packaging innovation in the domestic market.

Customizable for diverse product lines: Whether you produce small snacks or large meat products, our packaging lines are fully customizable to suit various product types and packaging formats.

Precision in deoxidizer integration: Our state-of-the-art deoxidizer dispensing system ensures that each package receives the correct amount of deoxidizer, eliminating errors and increasing production consistency.

Fully automated workflow: From product sorting to deoxidizer insertion, packaging, and sealing, the entire process is automated, reducing labor costs while enhancing operational efficiency.

Prolongs product freshness: The deoxidizer sachets help remove oxygen, ensuring longer shelf life and preserving product quality, ideal for food items prone to spoilage due to oxidation.

Application

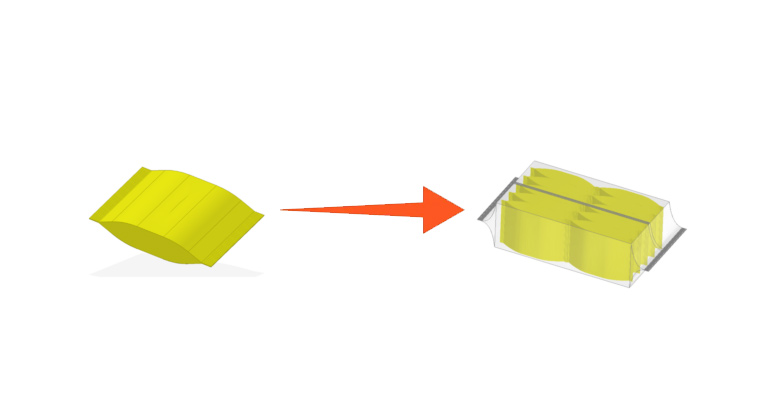

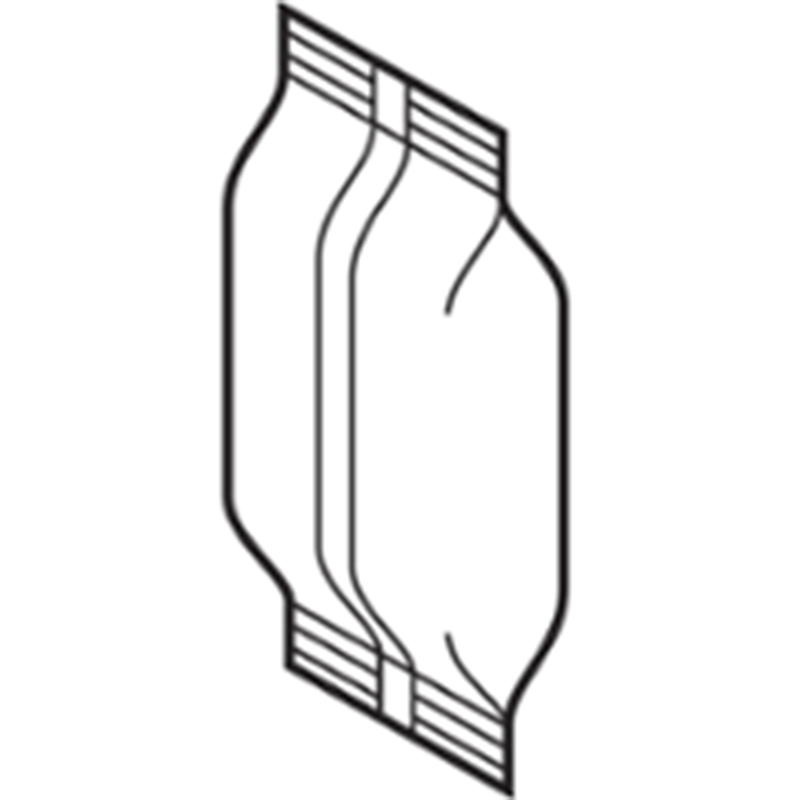

Bag Type

Optional Configuration