SI150DL On Edge Biscuit Packing Machine

SI150DL

Versatile Packaging Solution for Diverse Products

- Servo control

- Rotary motion end sealing

- External compressed air required

The SI150DL is the cost-effective version of the SI150L, equipped with an L-shape conveyor to enhance product feeding and transfer capabilities. This configuration combines the affordability of the SI150D with the advanced functionality of the conveyor system, offering manufacturers an economical yet efficient solution for on edge biscuit packing.

The SI150DL combines the cost-effectiveness of the SI150D with the advanced product handling capabilities of an L-shape conveyor. This makes it a versatile and efficient choice for manufacturers who need reliable on edge biscuit packing without exceeding their budget. With its ability to optimize workflows, save space, and maintain high packaging standards, the SI150DL is the perfect solution for cost-conscious, high-efficiency production environments.

Machine Parameters

| Specifications | SI150L (with L-shape conveyor) | SI150DL (with L-shape conveyor) | ||

| Bagging size range | L 130-400 mm | L 130-400 mm | ||

| W 30-140 mm | W 30-140 mm | |||

| Product size range | H 35-70 mm | H 35-70 mm | ||

| Packing speed | 30-110 bags/min | 30-110 bags/min | ||

| Packing fim width | 90-400 mm | 90-400 mm | ||

| Power supply | 220V /1Ph/50Hz | 220V/1Ph/50Hz | ||

| General power | 9.35 kW | 8 kW | ||

| Machine body material | Stainless steel | Carbon steel | ||

| Machine weight | 705 kg (without L-shape conveyor) | 448 kg (without L-shape conveyor) | ||

| Machine dimensions | 4042x3228x1638 mm | 3714x3229x1479 mm | ||

| Biscuit feeding | With L-shape conveyor for plain or sandwich biscuits | |||

| Packing material | OPP, PVC, OPP/CPP, PT/PE, KOP/CPPetc. | |||

| View Machine | ||||

Key Features

Economical L-Shape Conveyor Design: The integrated L-shape conveyor ensures smooth and efficient product feeding while maintaining cost-effectiveness, making it ideal for budget-conscious manufacturers.

Trayless On Edge Packing: Like the SI150DL’s counterparts, this machine excels in packing biscuits vertically without trays, reducing packaging material usage and optimizing space.

Compact and Efficient: With the L-shape conveyor, the machine efficiently handles product transfer between different production levels, saving floor space and streamlining workflows.

Reliable Performance: Advanced servo control technology ensures precise and consistent packaging, even in high-speed operations.

Cost-Effective Space Optimization: The L-shape conveyor elevates products efficiently, reducing the production line’s footprint and enhancing overall workflow efficiency.

Seamless Integration: Facilitates product transfer between production levels, making it suitable for factories with complex layouts or multi-level operations.

Improved Handling: Reduces manual labor by automating product feeding, enhancing production speed and reducing errors.

Adaptability: Designed to work seamlessly with different factory layouts, offering flexibility for diverse manufacturing needs.

Application

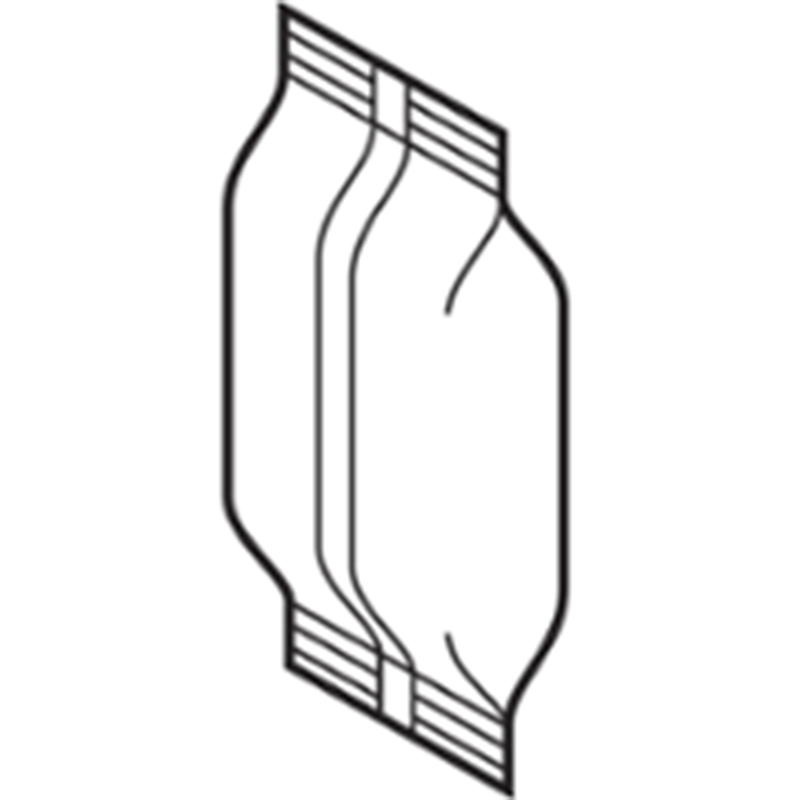

Bag Type

Optional Configuration