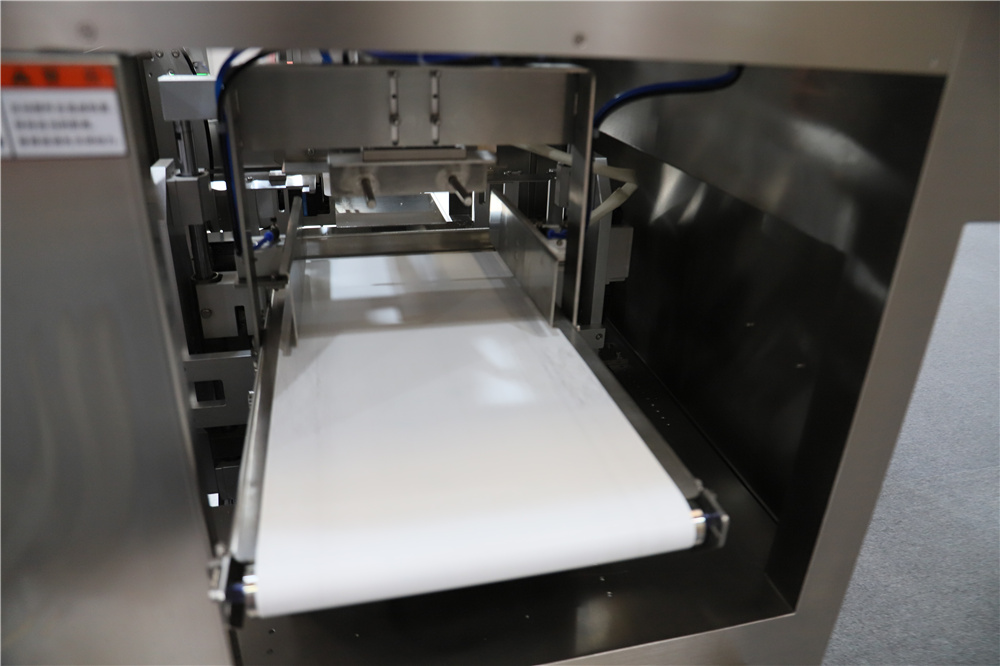

TD300A Horizontal Premade Pouch Packing Machine

TD300A

Versatile Packaging Solution for Diverse Products

- Servo control

- Stainless steel machine body

- External compressed air required

The TD300A is the upgraded version of the TD200A, designed to handle larger pre-made pouches in terms of length, width, and height. This makes it a perfect fit for manufacturers who require greater packaging flexibility. The machine retains the high-efficiency features of its predecessor, including quick mold changes and the ability to package irregularly shaped pouches, such as triangular bags.

With advanced servo control and a stainless steel body, the TD300A ensures consistent, high-precision packaging while maintaining the highest hygiene standards. Its horizontal rotary system guarantees smooth and efficient operation, making it ideal for industries like food and snacks that demand reliability and flexibility in packaging.

The TD300A offers all the advantages of the TD200A with the added benefit of handling larger pouches. Whether you're packaging snacks, baked goods, or other fixed-shape items, the TD300A provides greater flexibility, speed, and durability. With its servo control system and horizontal rotary operation, this machine is built to optimize production efficiency and meet diverse packaging needs.

Machine Parameters

| Specifications | TD200A | TD300A |

| Pouch length | 150-300 mm | 250-350 mm |

| Pouch width | 70-150 mm | 100-220 mm |

| Pouch height | 40-90 mm | 40-110 mm |

| Open-pouch speed | Max.60 pouches/min | Max.35 pouches/min |

| Sealed-pouch speed | Max.45 pouches/min | 25-30 pouches/min |

| General power | 8.0 Kw | 8.0 Kw |

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz |

| Machine weight | 500 kg | 600kg |

| Machine dimensions | 2000x970x1310 mm | 2460x1100x1500 mm |

| Packing material |

OPP/CPP, PT/PE, aluminum film, KOP/CPP aluminum laminated film |

|

| View Machine | ||

Key Features

Quick Mold Changes: The TD300A allows mold changes in around 10 minutes, significantly reducing downtime.

Handles Irregular Pouches: Capable of packaging irregularly shaped pouches, such as triangular bags.

Horizontal Rotary System: Ensures high-speed, precise, and consistent packaging for a wide range of products.

Servo Control System: Ensures precise and consistent operation, allowing for efficient and accurate pouch sealing.

Stainless Steel Machine Body: Guarantees durability, hygiene, and ease of maintenance, making it ideal for food-related industries.

Application

Bag Type

Optional Configuration

Quad seal bag assembly

Flat bottom bag assembly

Doy-style bag assembly

Gusset bag assembly

Washdown construction

Hole punch (Euroslot or Round)

Product settler

Gas flush

Static elimination

Tear notch

Remote diagnostics

Integration with variety of fllers,printers,metal detectors,label applicators,and checkweighers